Although our company has not obtained ISO certification, we have established the high standard of quality control system in accordance with ISO standards. Specifically, we are implementing the following initiatives

All products are manufactured through

the strict quality control process,

and undergo the rigorous inspection before shipping.

We continuously implement

the PDCA cycle (Plan, Do, Check, Act)

for the quality improvement and make our product better to meet our customers' needs.

We are constantly improvingour products to

meet our customers' needs and strive to respond quickly to changing demands.

We conduct the quality control training

for all employees regularly, and therefore,

they approach their work with the latest skills and knowledge.

We value customer feedback and based on it,

we strive to improve the quality of our products.

Through these efforts, we have established a quality control system comparable to ISO certification and are committed to providing the high-quality products. As a trusted partner, we will continue to strive for the quality improvement.

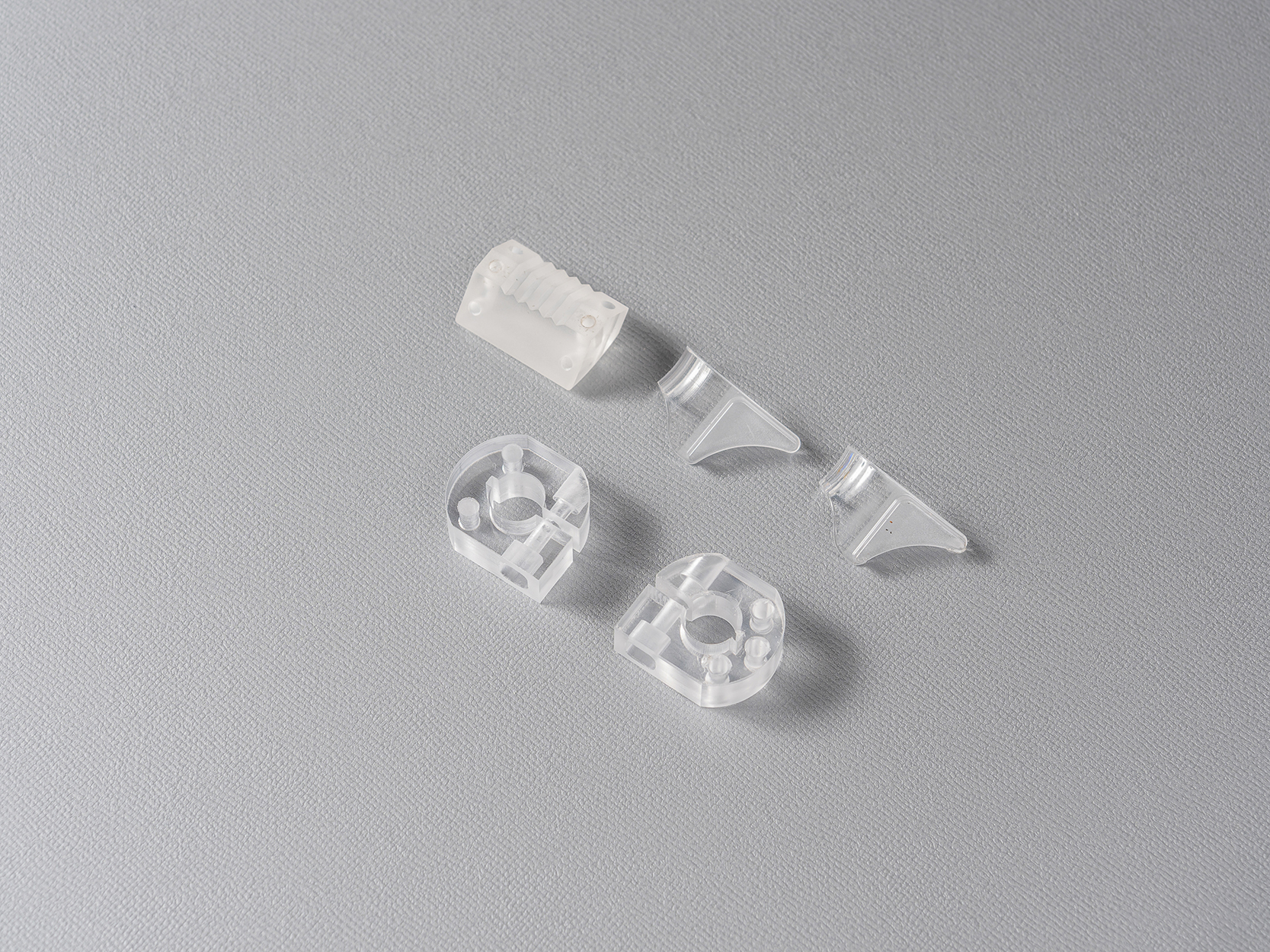

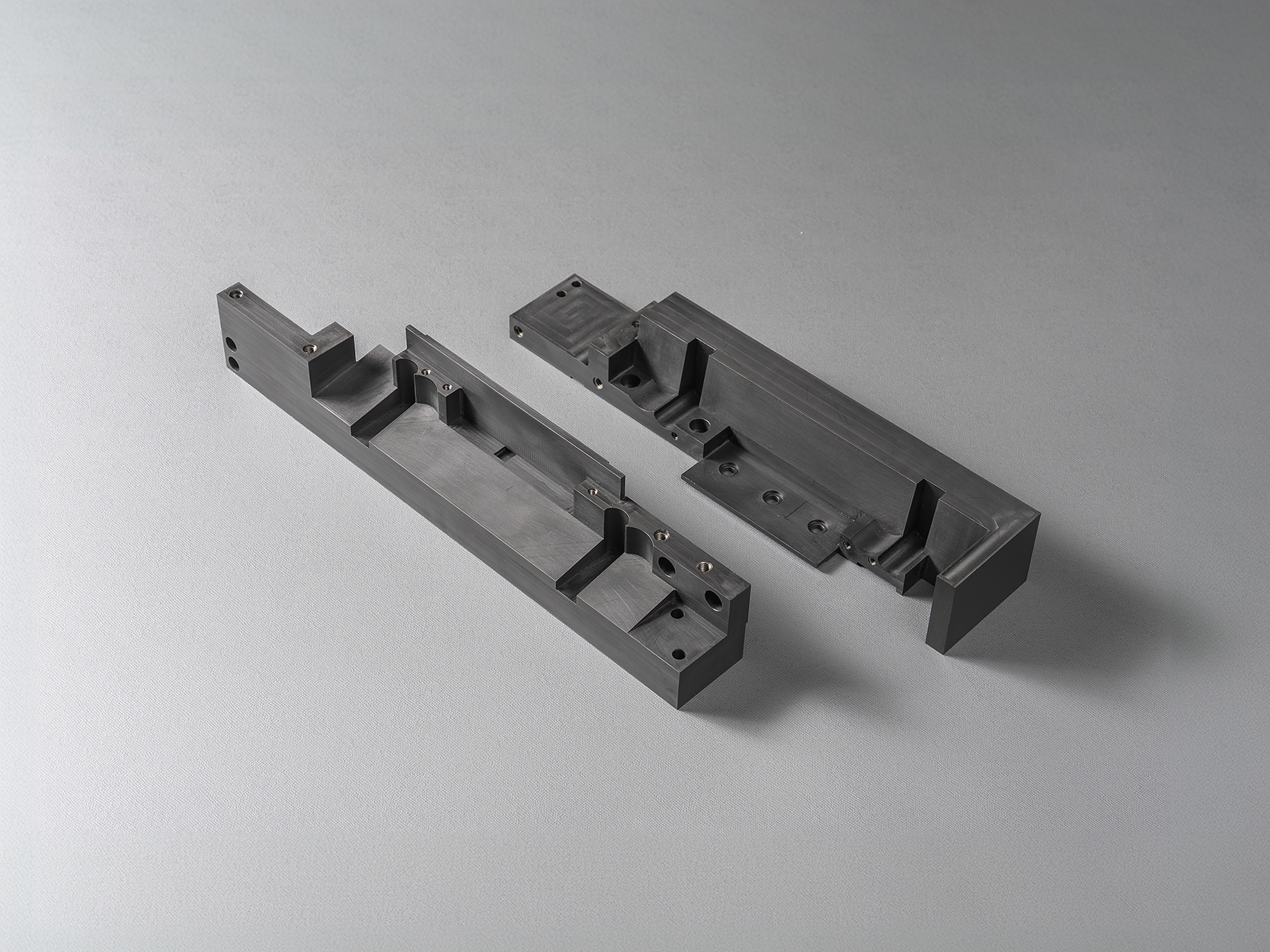

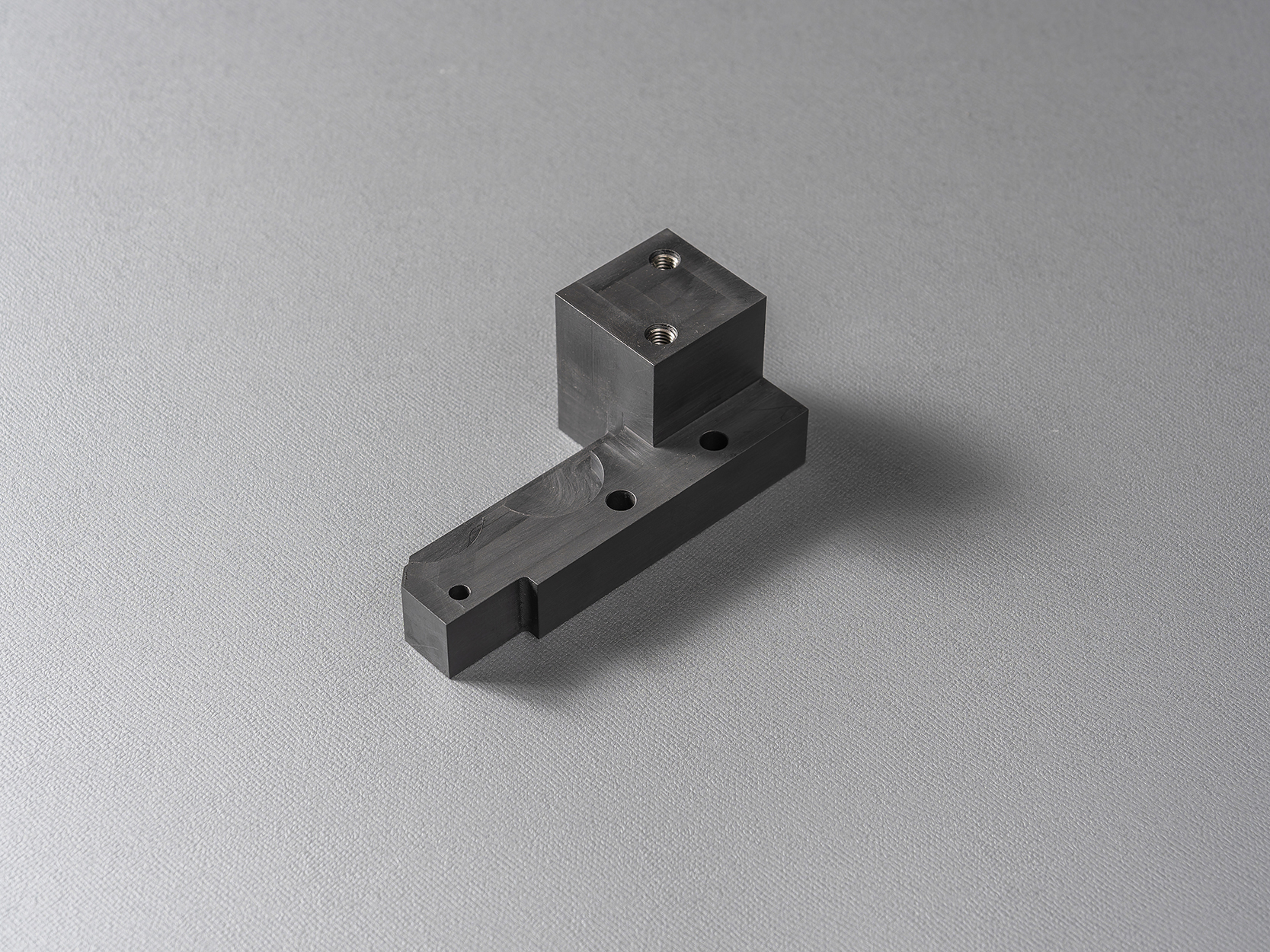

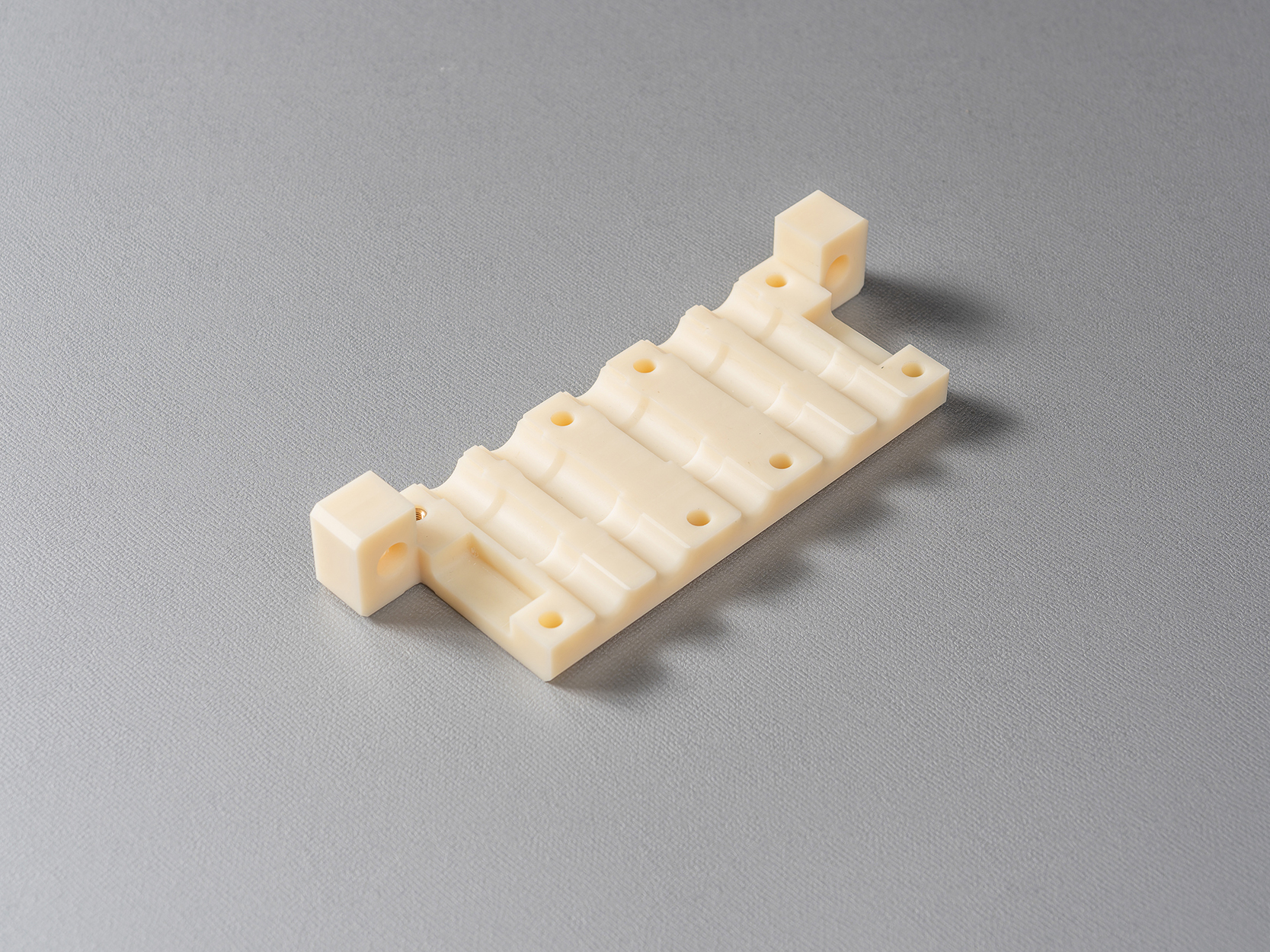

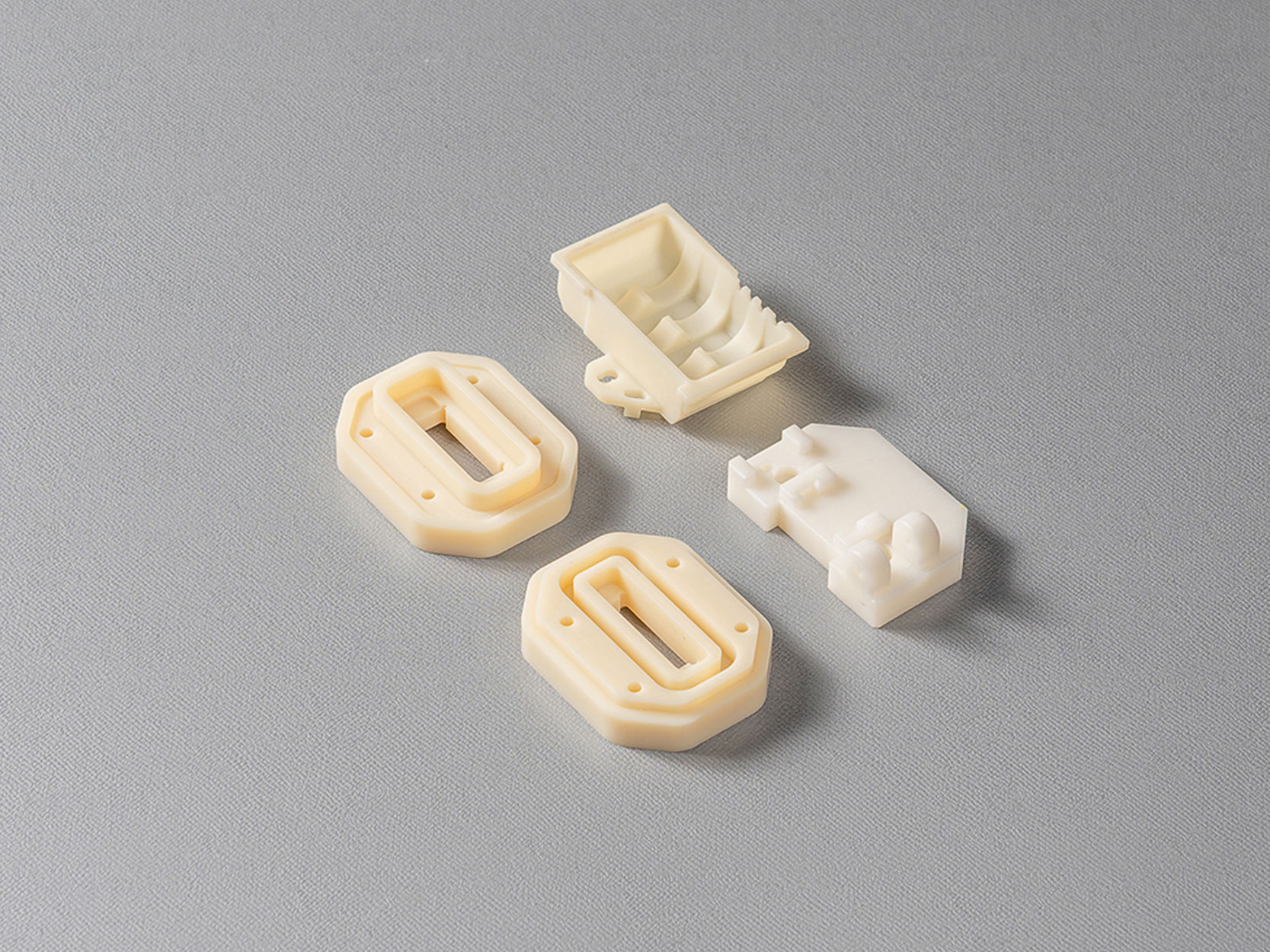

We use CNC (Computer Numerical Control) machines, milling machines, and other precision tools to shape resin materials, such as plastics, into your desired shapes and dimensions. Resin machining is ideal for parts that require high dimensional accuracy, prototypes, and small lot production, allowing us to produce lightweight yet durable components. We’ll meet your needs emphasizing functionality and quality, as our process is adaptable to various resin materials depending on product requirements.

POM (Polyacetal)

POM, or polyacetal, is the best material for parts requiring long life because it has excellent strength, wear resistance and low friction. In addition, POM offers high dimensional stability, which is why it is widely used for gears, bearings, sliders and other precision machine parts. It is also easy to machine, allowing us to achieve complex shapes and high-precision finishes.

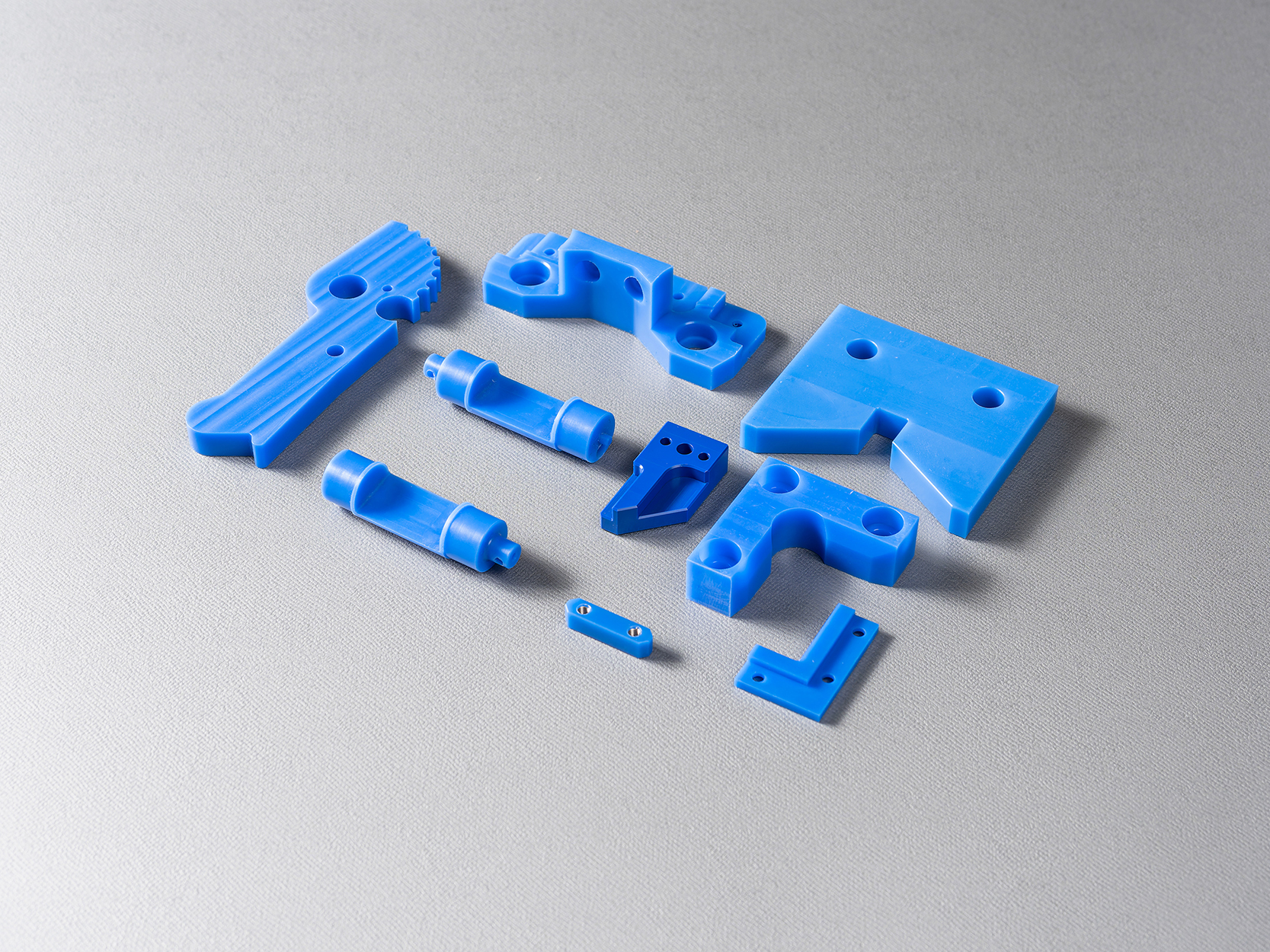

MC Nylon

MC Nylon (Monomer Casting Nylon) is a resin material with exceptional wear resistance, impact resistance, and self-lubricating properties, making it particularly suitable for machined parts. It is lightweight yet tough, so it's used in a wide range of applications for mechanical components that undergo wear and impact, such as gears, sprockets, rollers, and guide parts. It is also an effective alternative to metals, helping to improve the durability of parts and reduce costs.

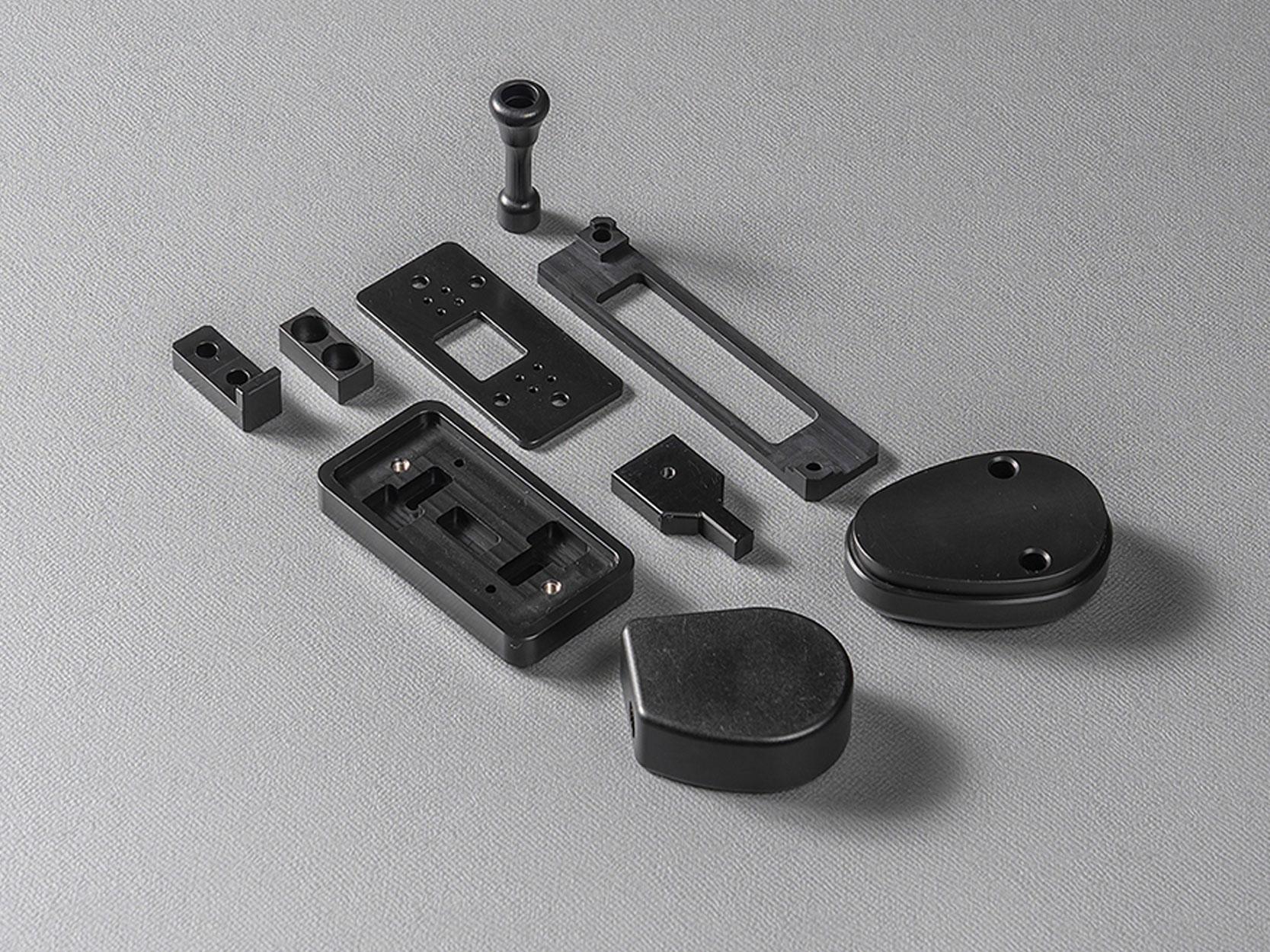

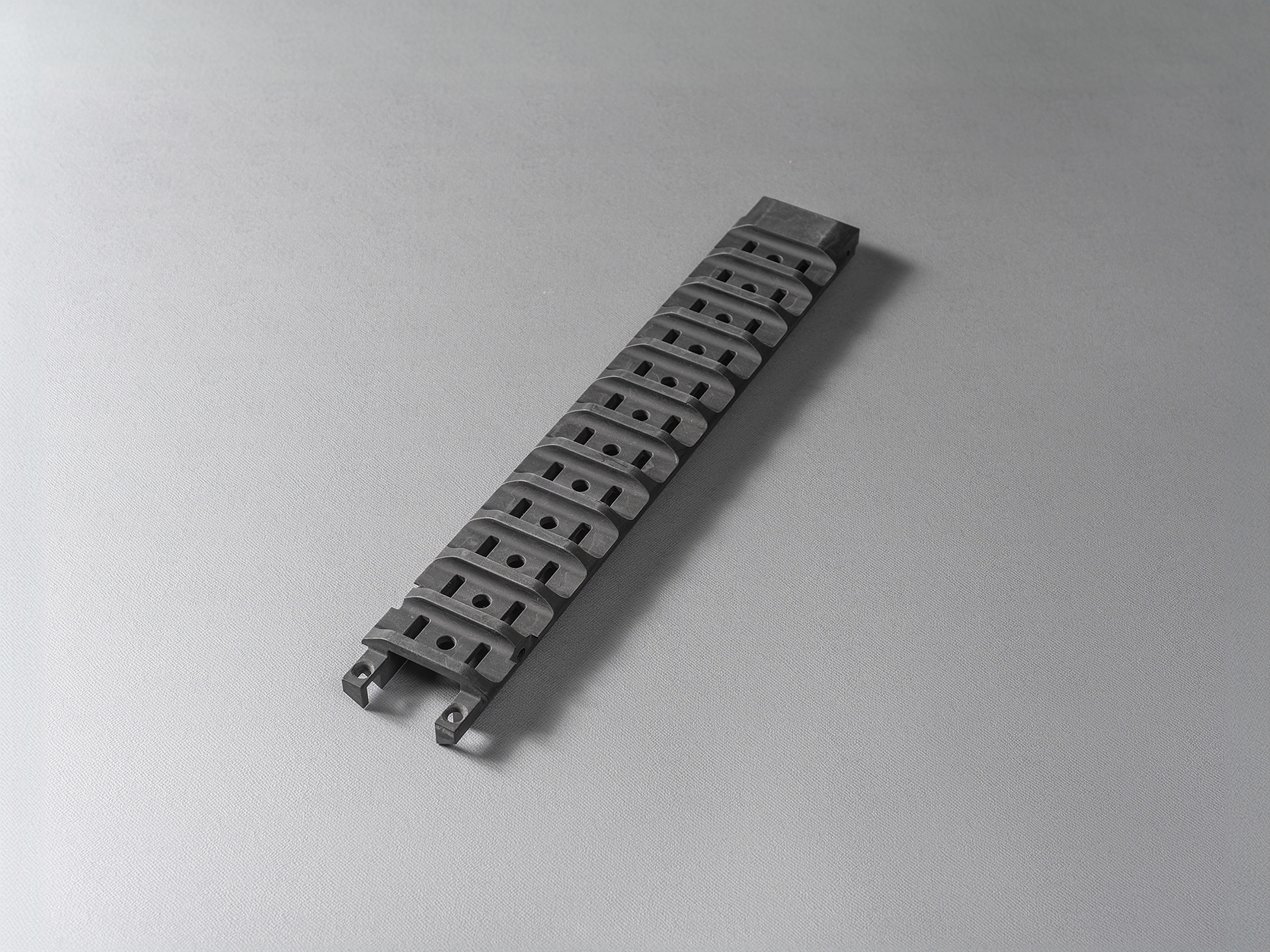

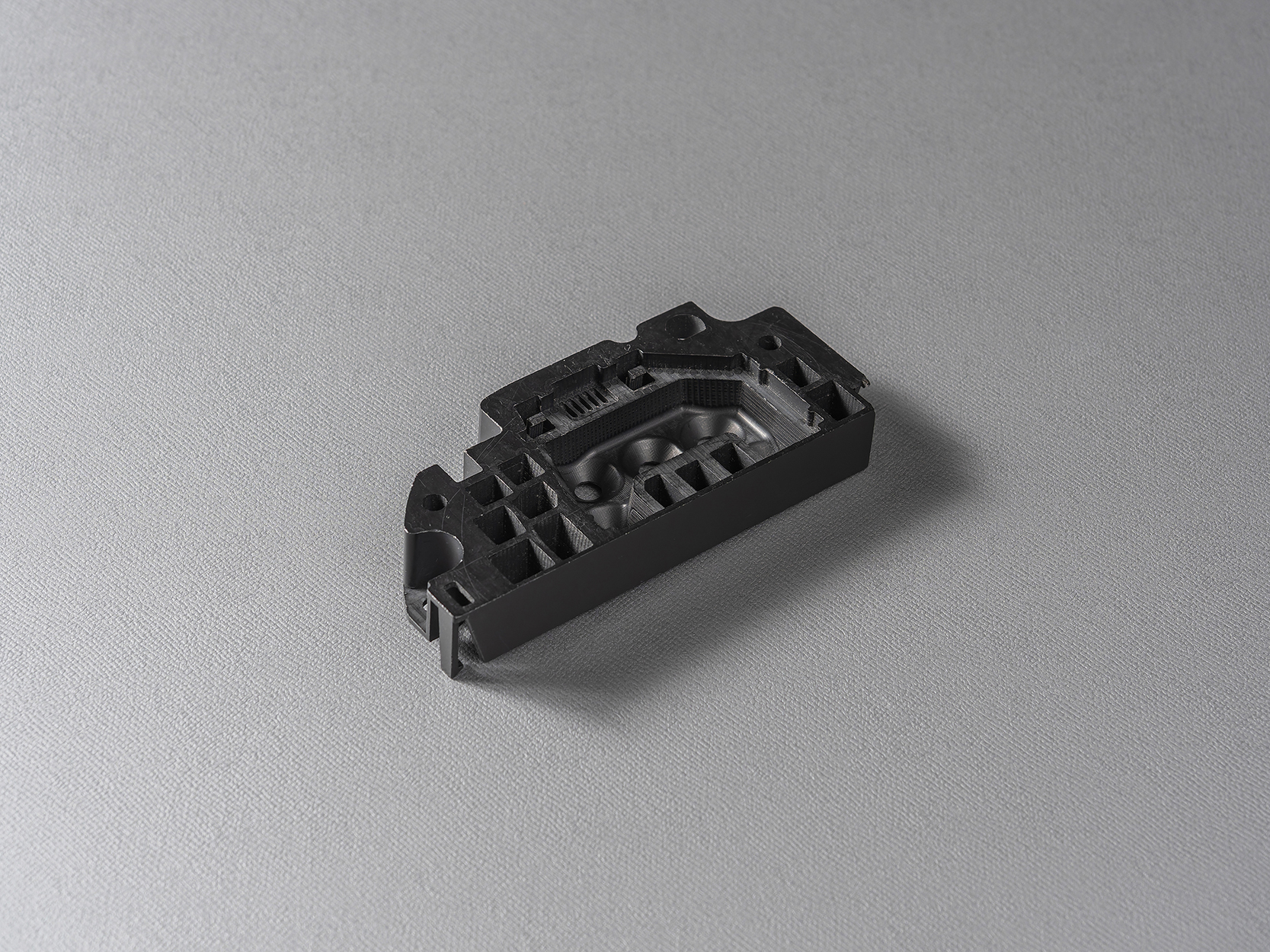

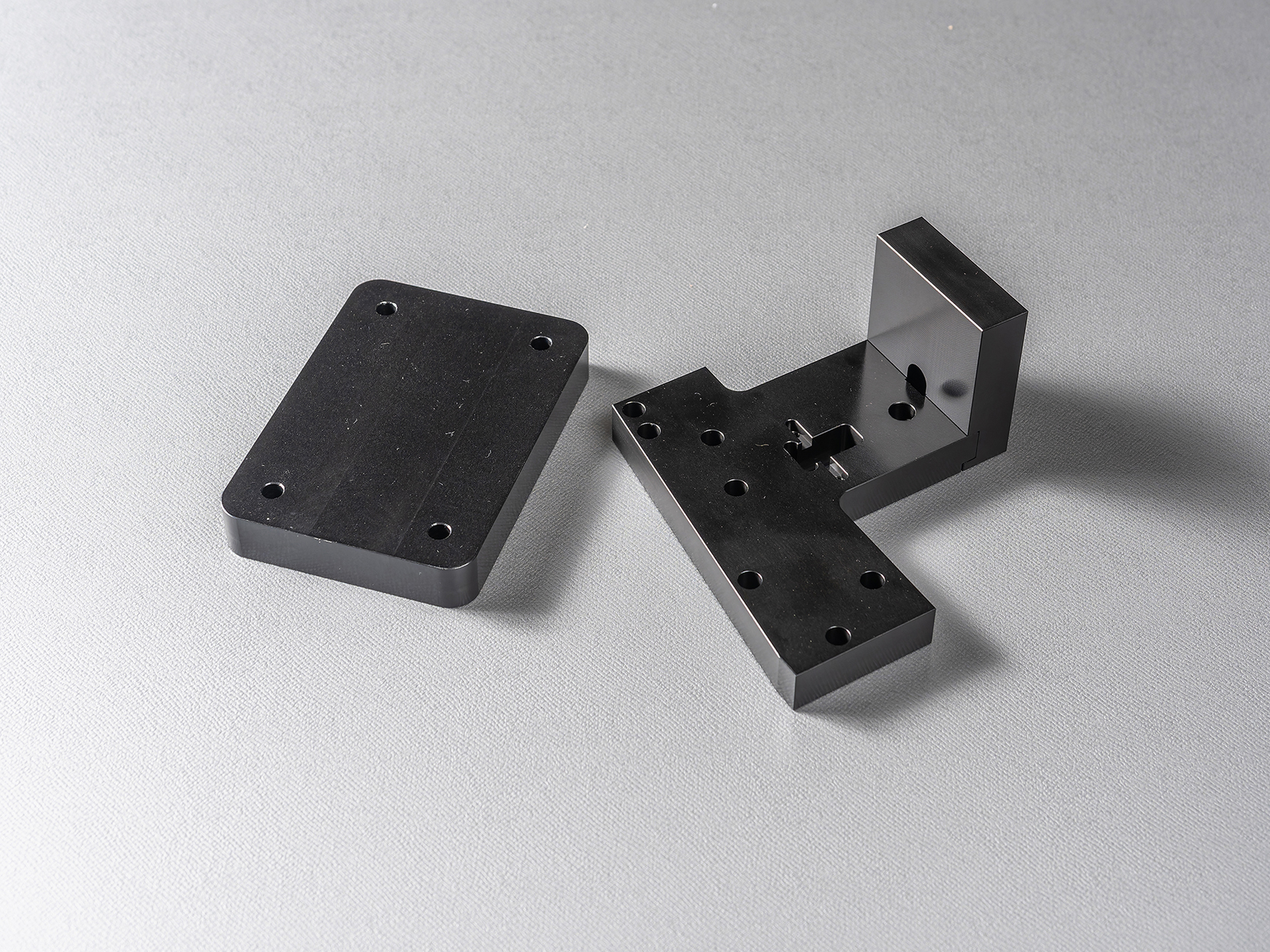

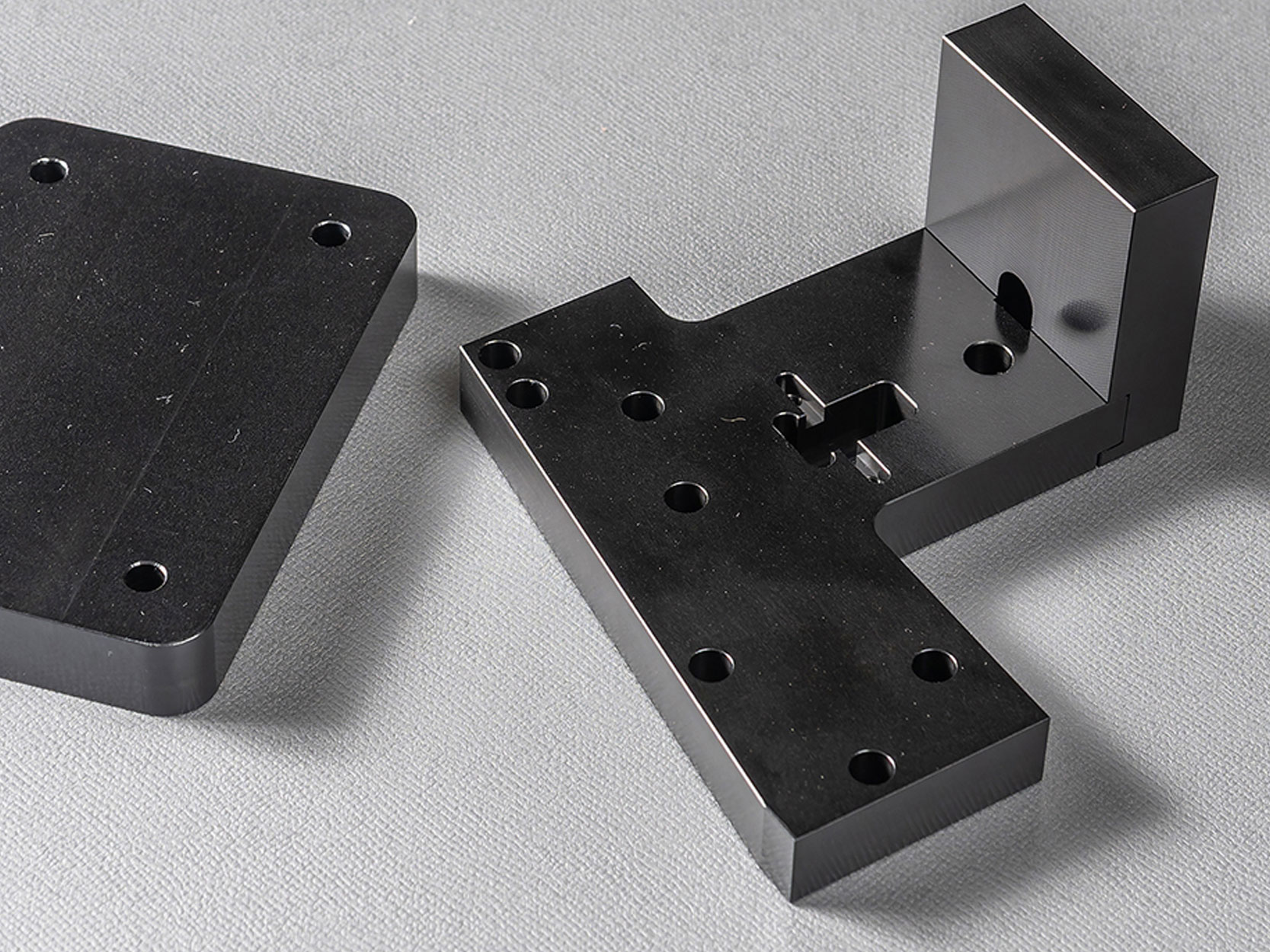

Black Resin

Black resin is known for its excellent durability and wear resistance, providing an attractive appearance that makes it easy to distinguish components. It also offers high dimensional accuracy, making it suitable for a wide range of applications such as precision instruments and automotive parts.

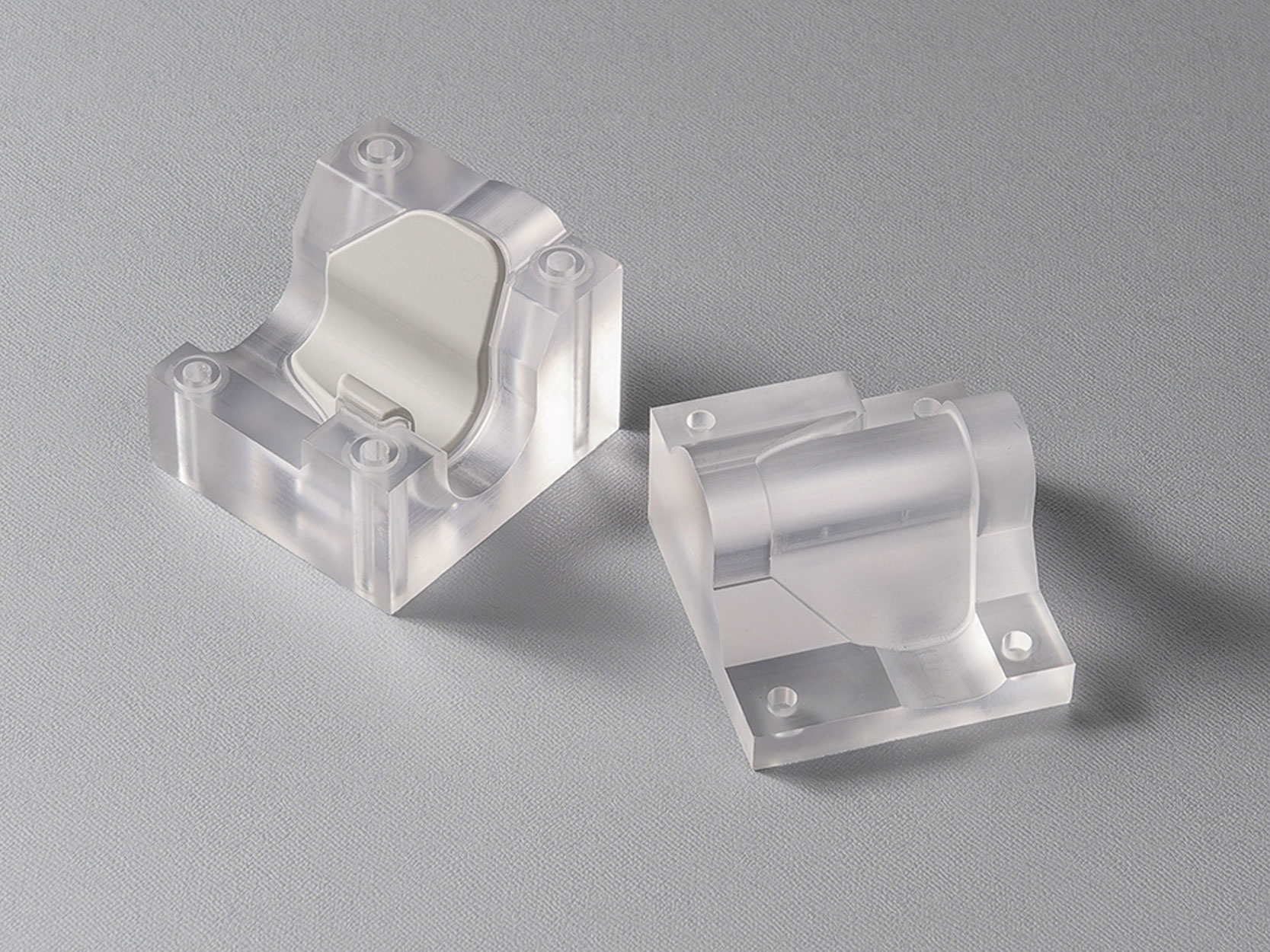

Acrylic and Polycarbonate

Acrylic and polycarbonate machining products are known for their high transparency and excellent impact resistance. They are widely used for applications such as display cases, protective covers, and optical components. These materials offer excellent machinability, allowing us to create precise shapes and smooth surfaces while providing durability.

Bakelite

Bakelite is known for its excellent electrical insulation and heat resistance, making it a popular choice for precision machine parts and insulation materials in electrical and electronic devices. Its high chemical resistance also makes it suitable for parts used in special environments. Additionally, its dimensional stability allows it to be machined into complex shapes with high precision.

MC Nylon

MC Nylon (Monomer Casting Nylon) is a resin material with exceptional wear resistance, impact resistance, and self-lubricating properties, making it particularly suitable for machined parts. It is lightweight yet tough, so it's used in a wide range of applications for mechanical components that undergo wear and impact, such as gears, sprockets, rollers, and guide parts. It is also an effective alternative to metals, helping to improve the durability of parts and reduce costs.

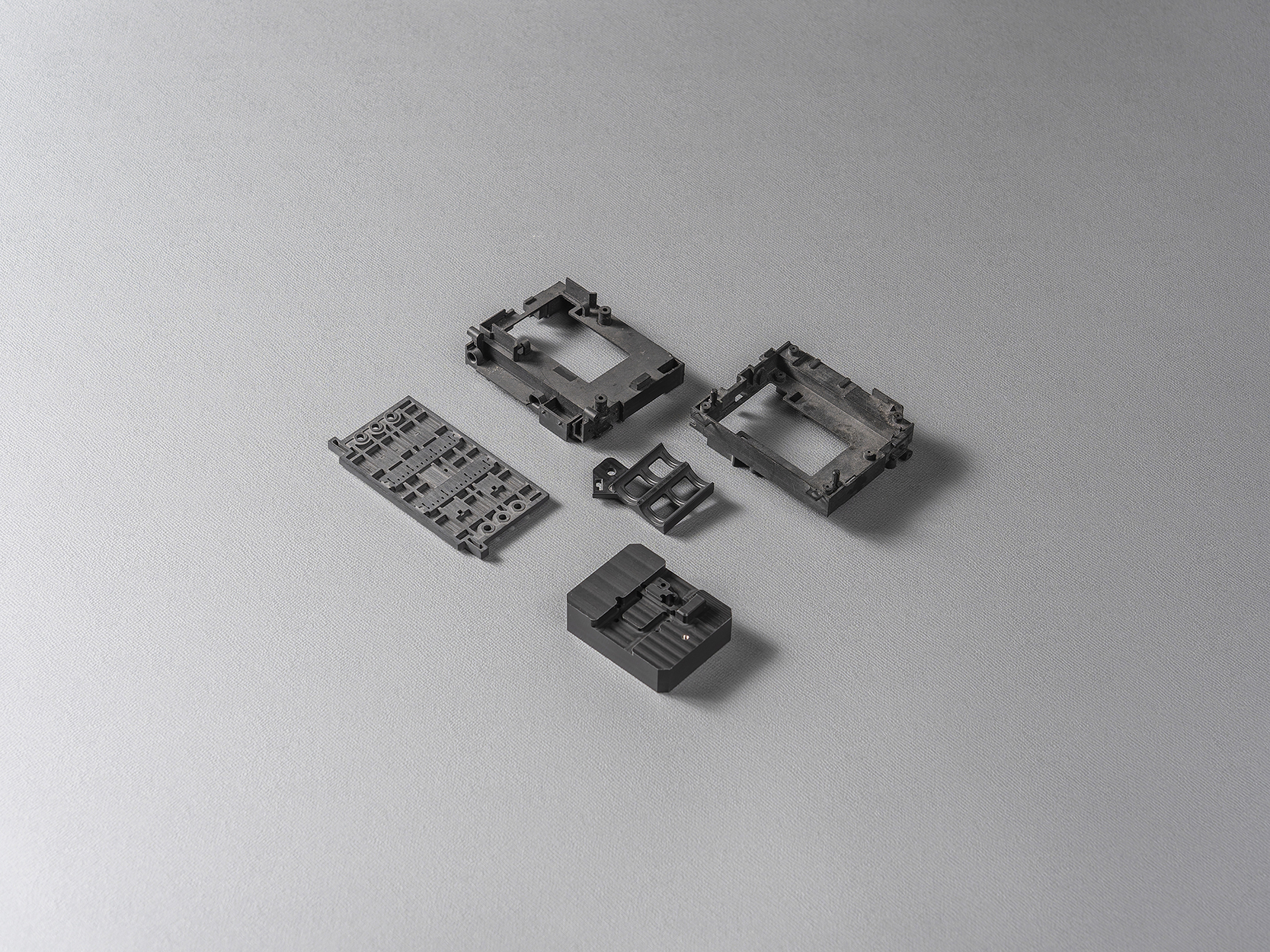

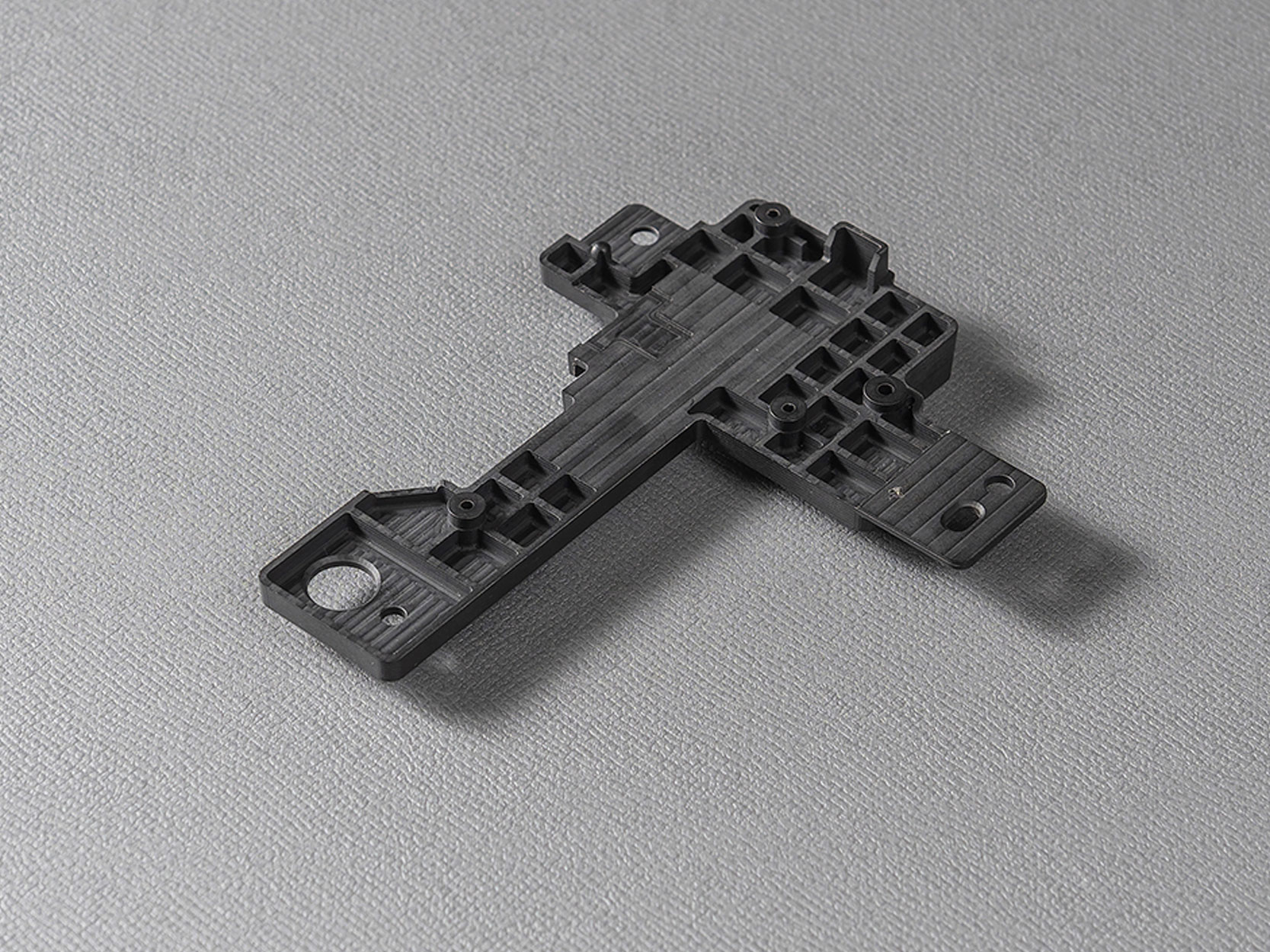

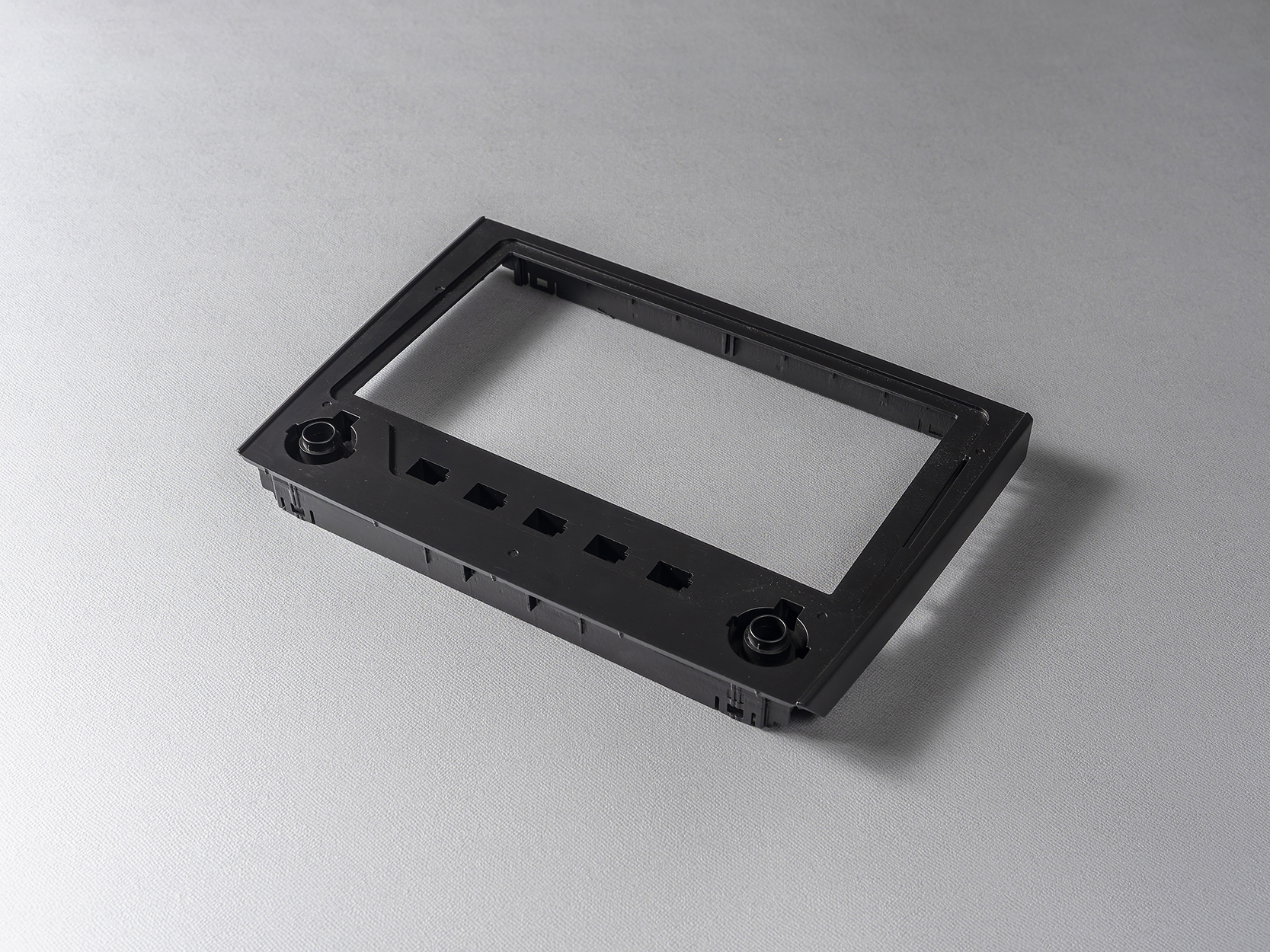

Antistatic ABS

Antistatic ABS is a type of ABS resin that is processed into components that help reduce the generation of static electricity. It offers the excellent impact resistance and the machinability, making it suitable for use in electronic devices and precision components. This material is ideal for the environments where the static electricity control is essential and also helps prevent the adhesion of dust and debris.

Acrylic

Acrylic is known for its high transparency and beautiful gloss, making it ideal for the products that require a glass-like appearance. It offers excellent precision in machining, allowing the reproduction of complex shapes with smooth edges after machining. Additionally, it is lightweight yet durable, making it suitable for both indoor and outdoor use. It is also resistant to yellowing from UV light.

ABS

ABS is characterized by excellent impact resistance, heat resistance, high dimensional stability and the ability to be precisely machined. ABS resin is easy to process, has a smooth and aesthetically pleasing surface, and allows for easy finishes such as painting and plating. Additionally, it is lightweight and electrically insulating, making it suitable for a wide range of applications, including industrial parts, prototypes and household appliances.

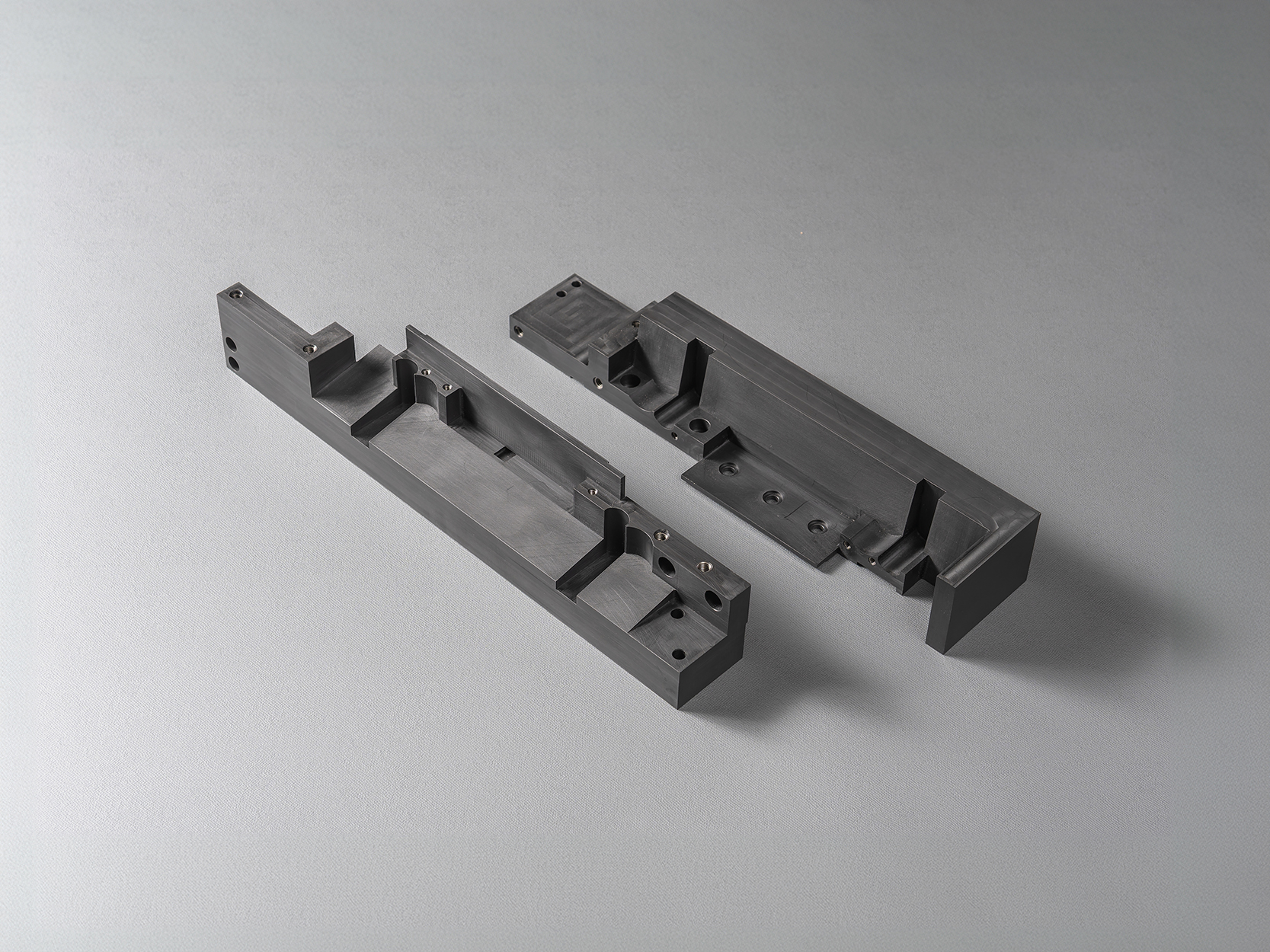

Manufacturing nonferrous metals involves the technology to process metals that do not contain iron, such as aluminum, copper, and brass. Nonferrous metals are lightweight and highly resistant to corrosion, and have the excellent electrical and thermal conductivity, making them widely used in industries such as automotive, electronics, and aerospace. Through machining, it is easy to create the products with precise dimensions and shapes, and the complex processing tailored to specific applications is also possible.

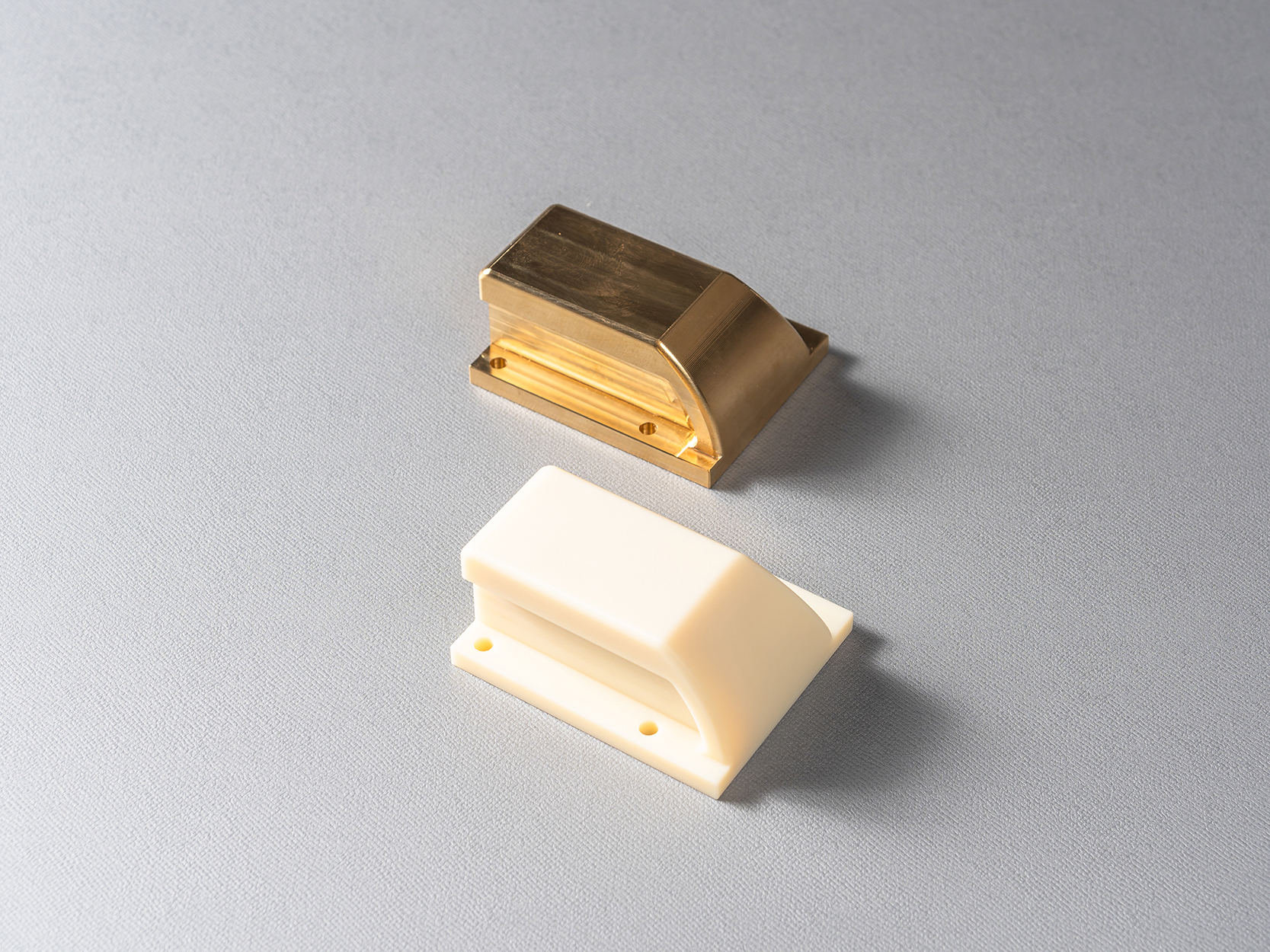

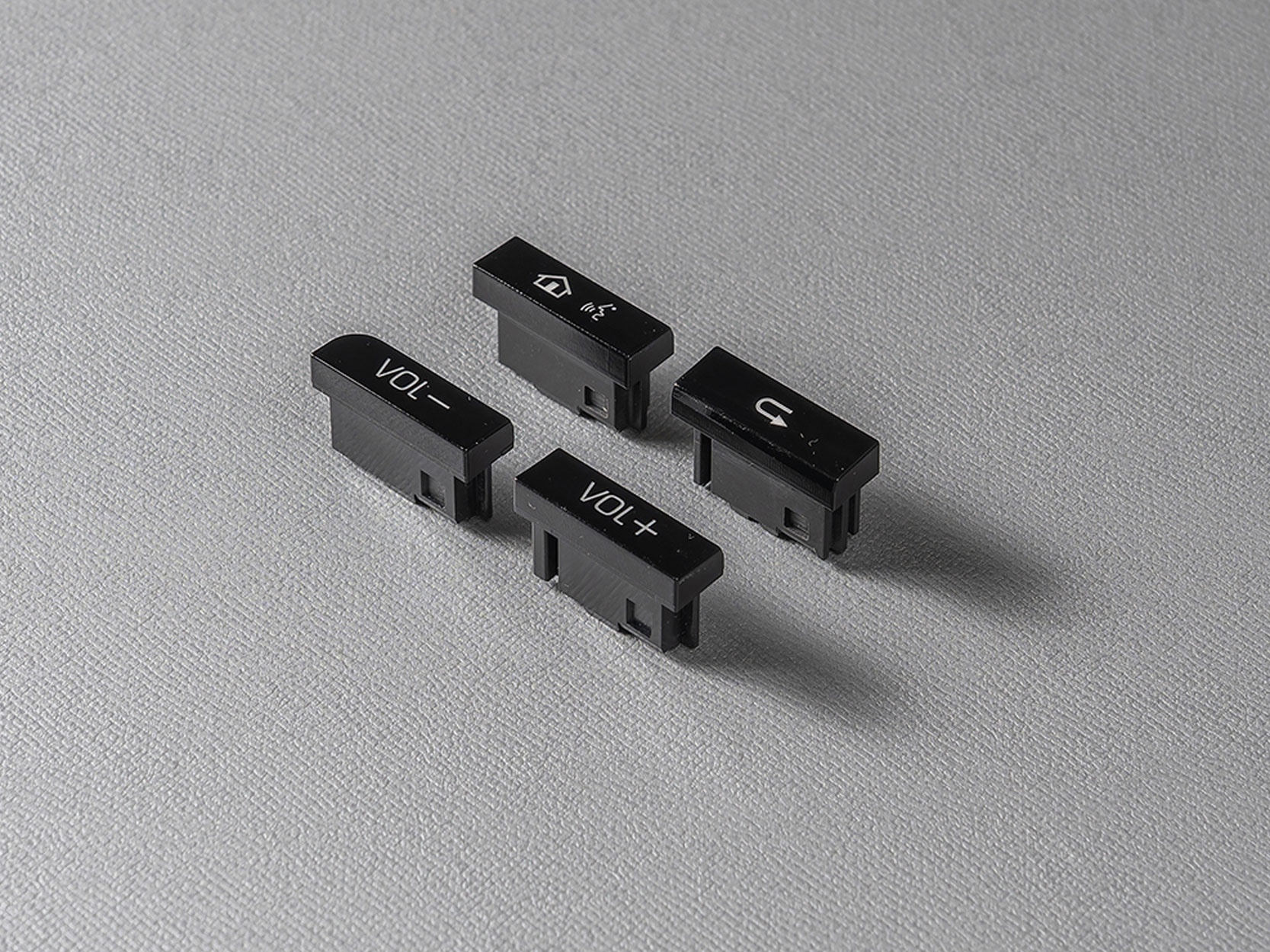

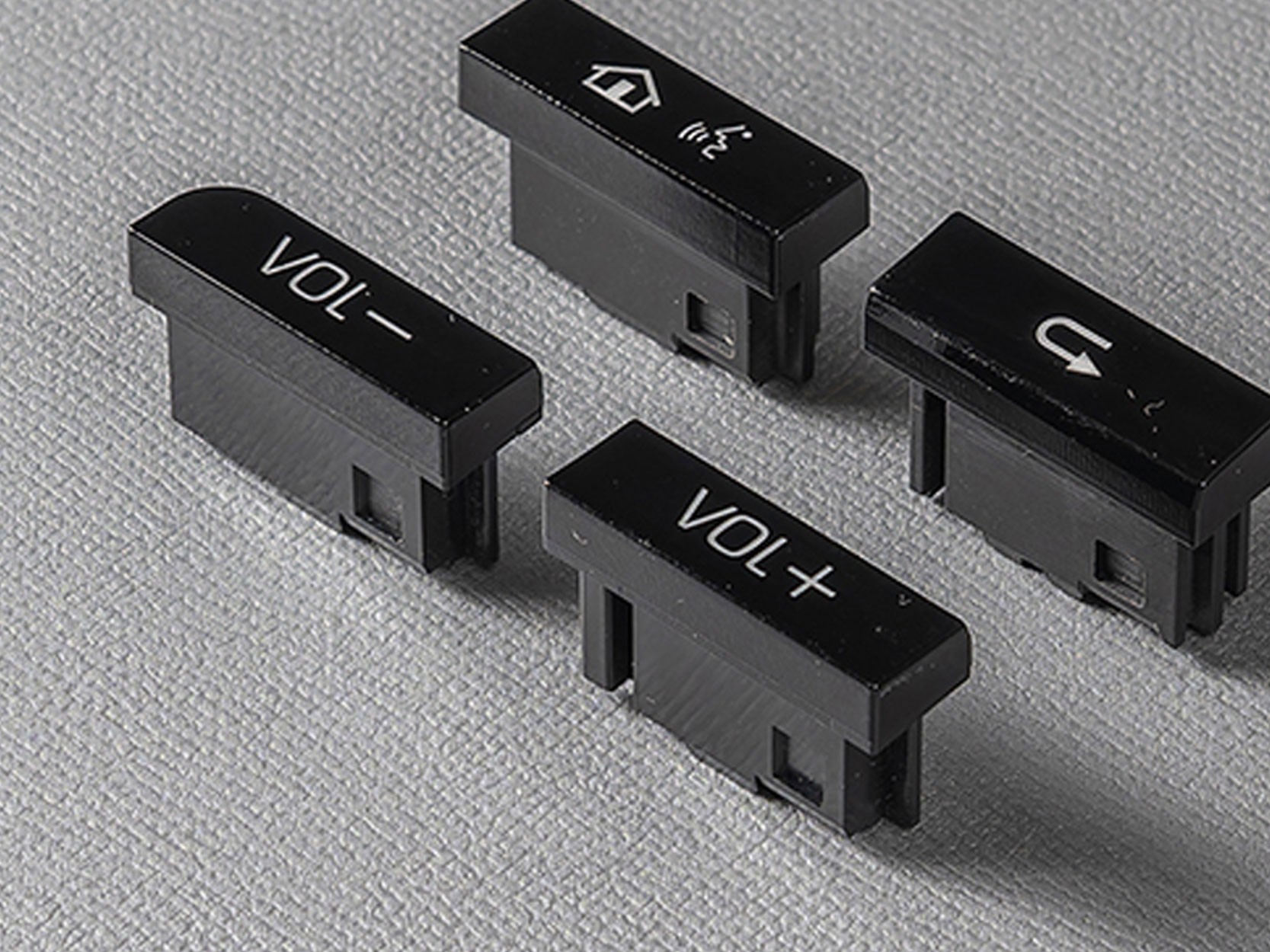

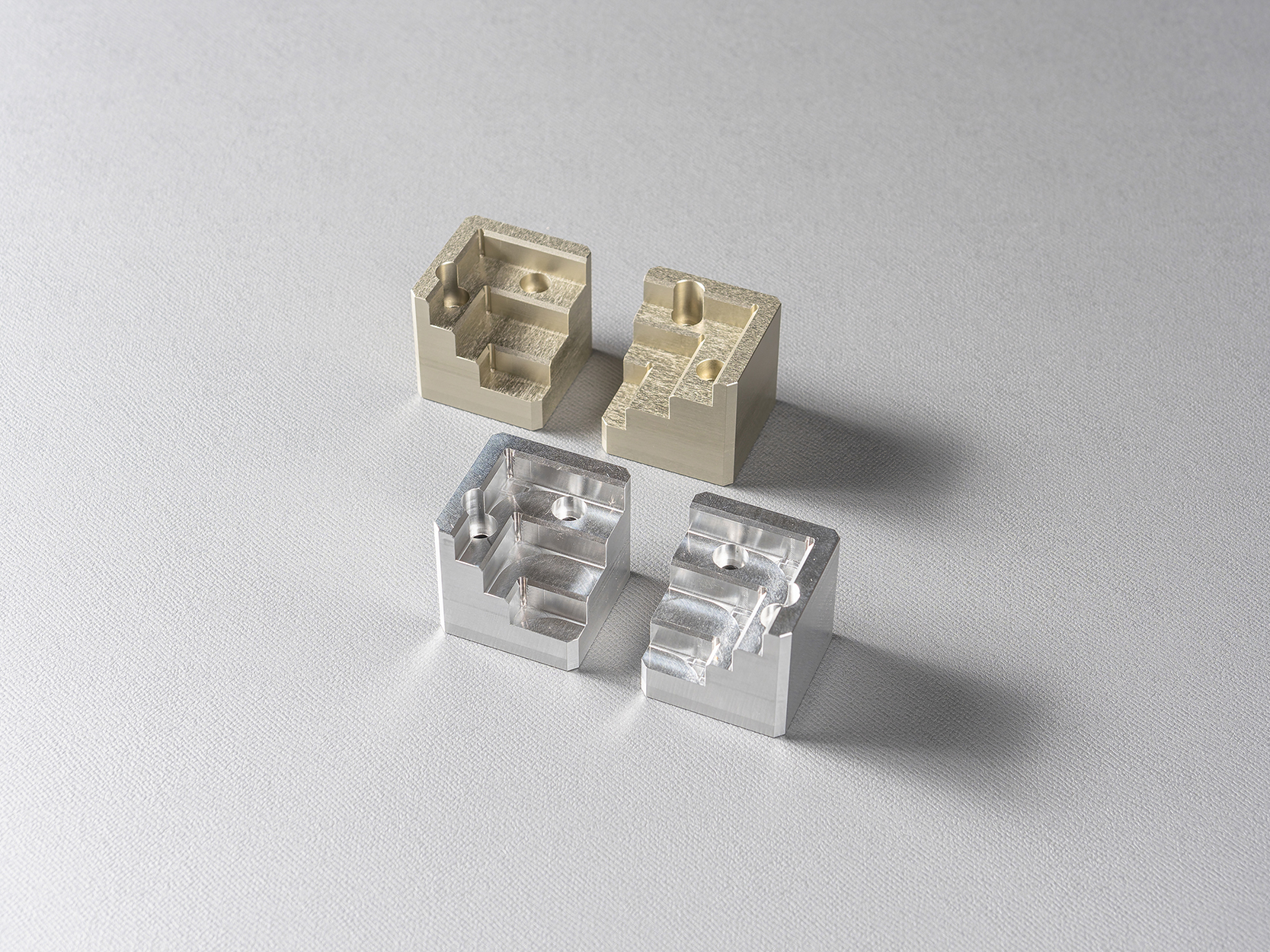

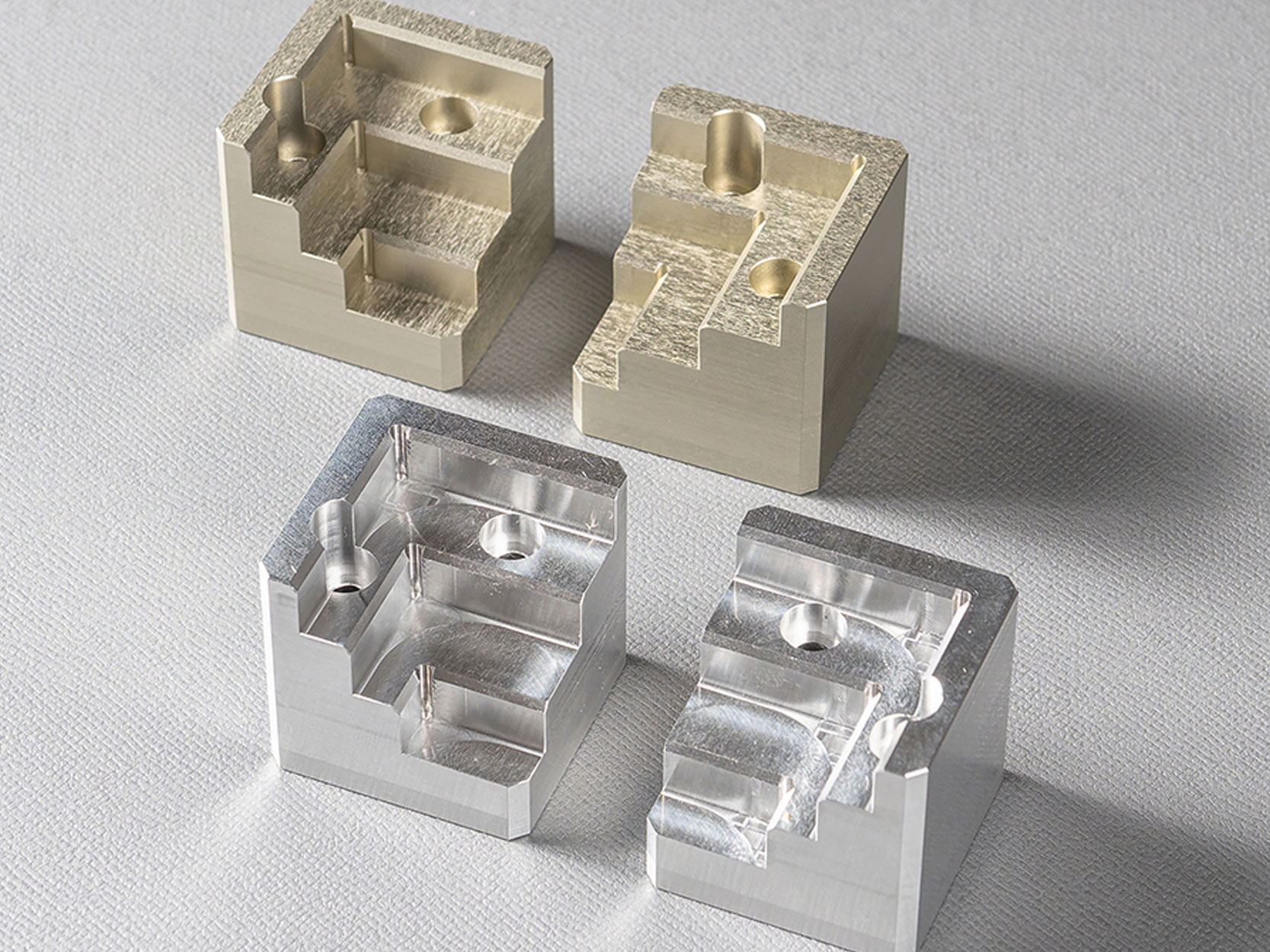

ABS (Bottom) / Brass (Top)

ABS machined parts are lightweight, highly impact and chemical resistant, with good electrical insulation properties, so they're suitable for prototypes and electronic components. On the other hand, brass machined parts offer high strength, excellent corrosion resistance, and high machining precision. Their decorative appearance and conductivity make them ideal for precision components and contact parts.

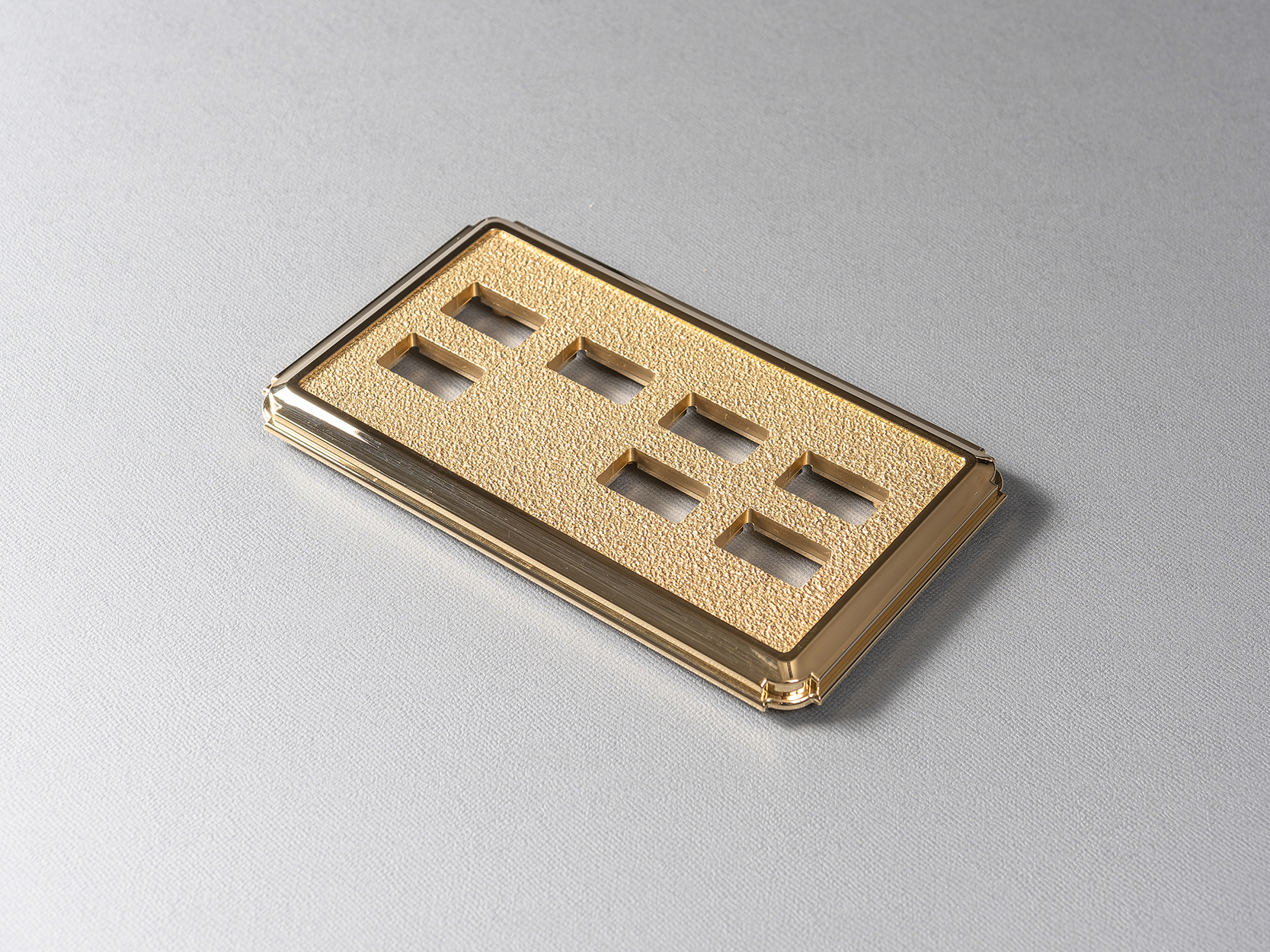

Brass Casting + ABS Molding (Gold Plating)

Brass casting combined with ABS molding (gold plating) is a processing method that balances durability and aesthetics. High strength and precision are achieved through brass casting and precise machining, while the combination with ABS molding results in a lightweight structure. Gold plating adds a sense of luxury and improves corrosion resistance, making it ideal for precision parts and the decorative items.

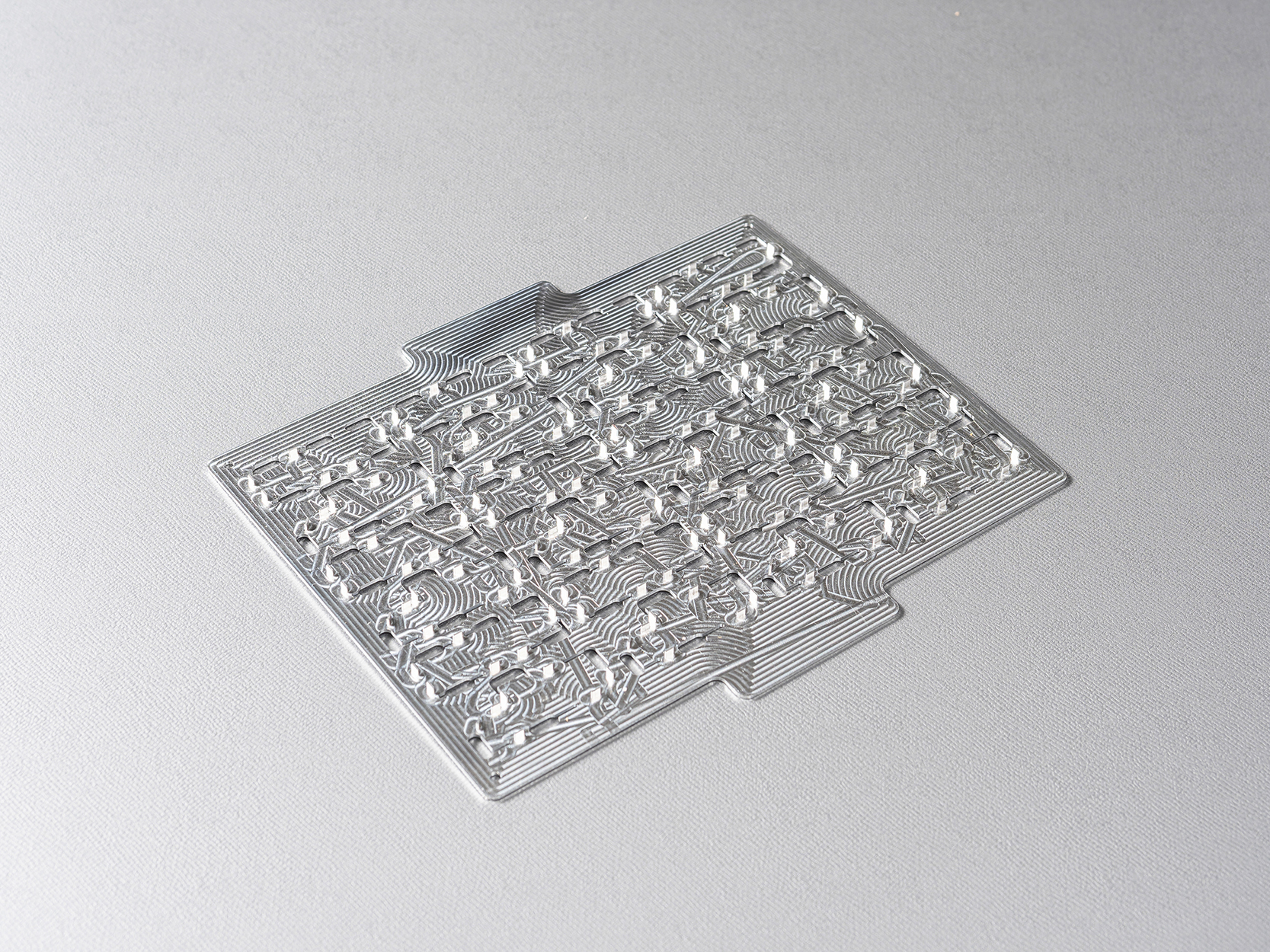

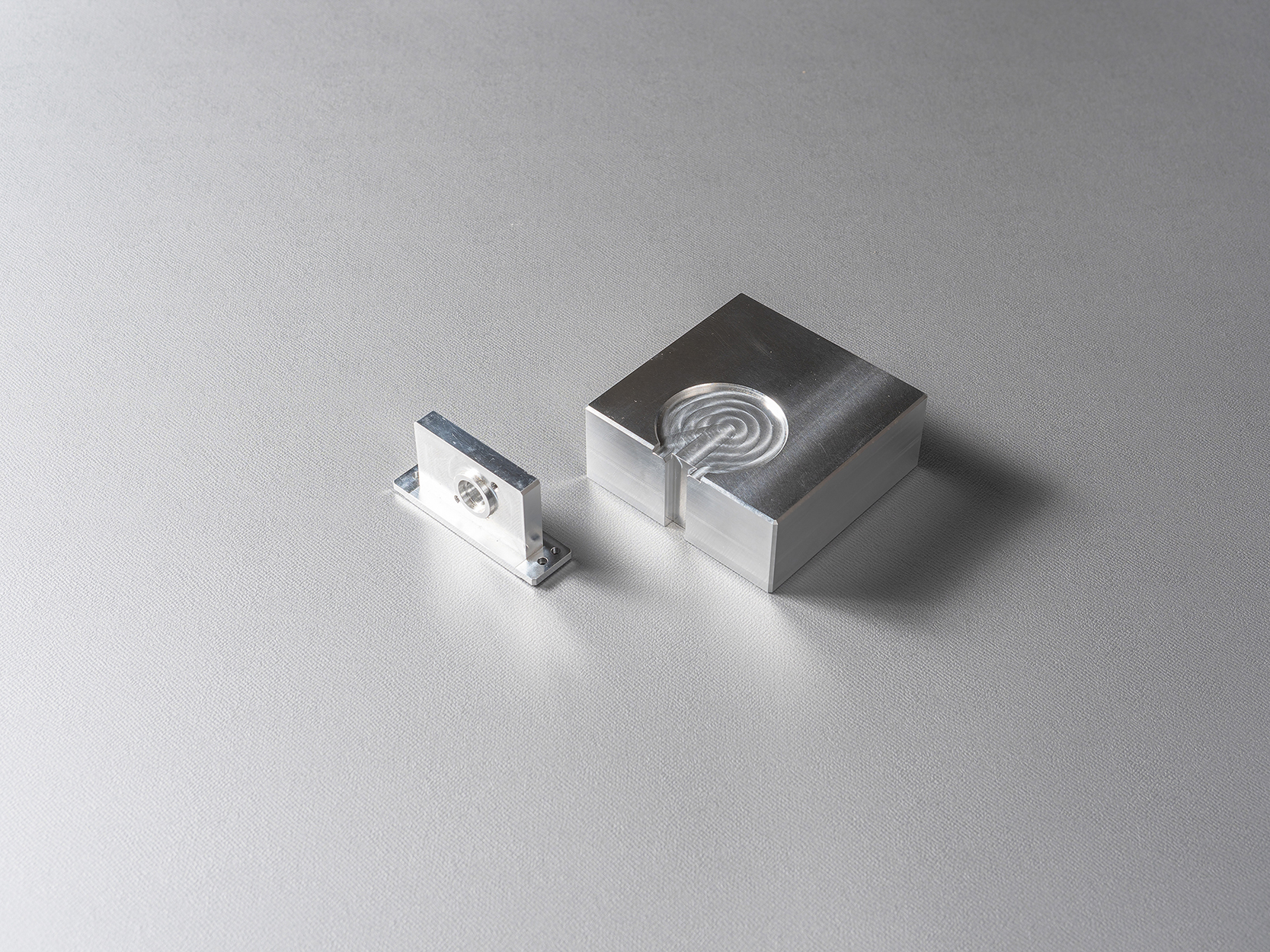

Aluminum

The features of aluminum are lightweight yet strong, highly resistant to corrosion, and having excellent thermal conductivity. It is also easy to machine, allowing for the creation of complex shapes and high-precision finishes. Aluminum is used in a wide range of applications, including automotive, aerospace, and electronic components.

Surface treatment of resin and aluminum is a critical process that enhances both the durability and appearance of the products. It helps prevent the corrosion and wear, and maintain their color and texture. Common treatment methods include painting, plating, and coating. High-quality surface treatments help extend product life and increase the customer satisfaction.

ABS Mirror Finish

The mirror finish on ABS is a process to improve the smoothness and gloss of the surface. First, the surface is polished to remove roughness after machining, and then finer abrasives or polishing agents are used to complete the finish. This process improves the reflectivity and gives the surface an aesthetically pleasing appearance. Additionally, the mirror finish also improves durability and chemical resistance.

Conductive Coating

Conductive coating is a process that involves applying a special paint with electrical conductivity to the surface of an object. This coating is primarily used for shielding electronic devices, preventing electrostatic discharge, grounding, or manufacturing conductive components. By incorporating metal powders or carbon, it achieves electrical conductivity and can be applied to various materials. Conductive coatings are valued in many industries due to their light weight and ease of processing.

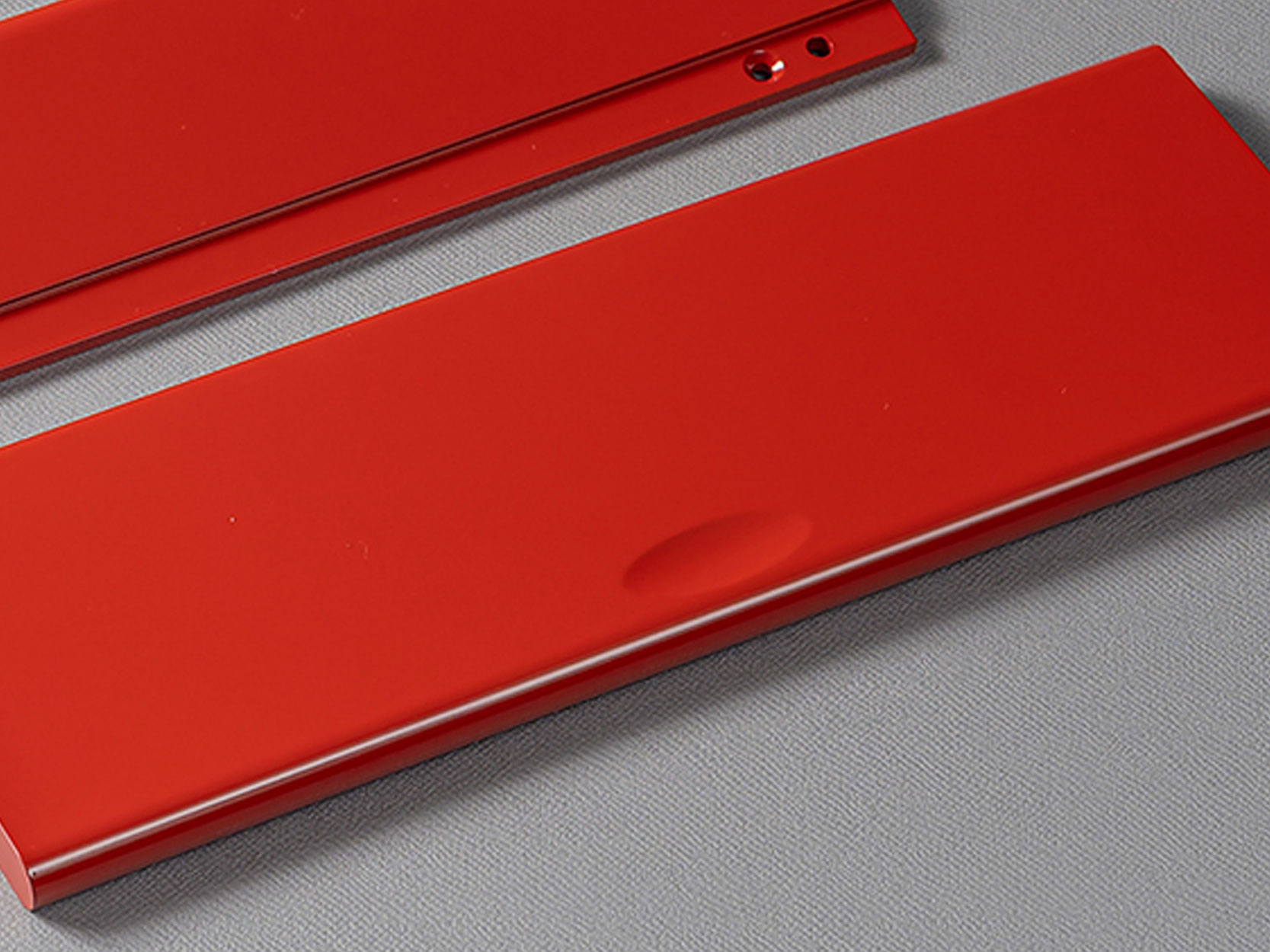

Glossy Paint

Glossy coating is an advanced painting technique that provides a smooth and lustrous finish to surfaces. This finish is highly reflective, and enhances visual appeal, making it widely used in industries such as automotive, furniture, and electronics. Additionally, one of its key features is the ability to adjust the level of gloss depending on the type of paint used.

Laser Marking

Laser marking is a manufacturing technology that uses laser beams to create high-precision markings on the surface of materials. By utilizing the thermal energy of the laser, the material can be discolored or coatings can be removed to engrave highly visible text, logos, or designs. Because of its high precision and durability, this technology is widely employed for product identification and tracking, and it can be applied to a variety of materials, including metals and plastics.

Aluminum (bottom) and Hard Anodized Aluminum (top)

Aluminum (bottom) has precise shapes and dimensions, is lightweight, and offers excellent corrosion resistance. It also has high machinability, allowing to customize according to the various applications. On the other hand, hard anodized aluminum (top) forms a thick oxide layer on the surface which increases wear and corrosion resistance. It has a vibrant, aesthetically pleasing finish and significantly improves both the durability and appearance of the product.

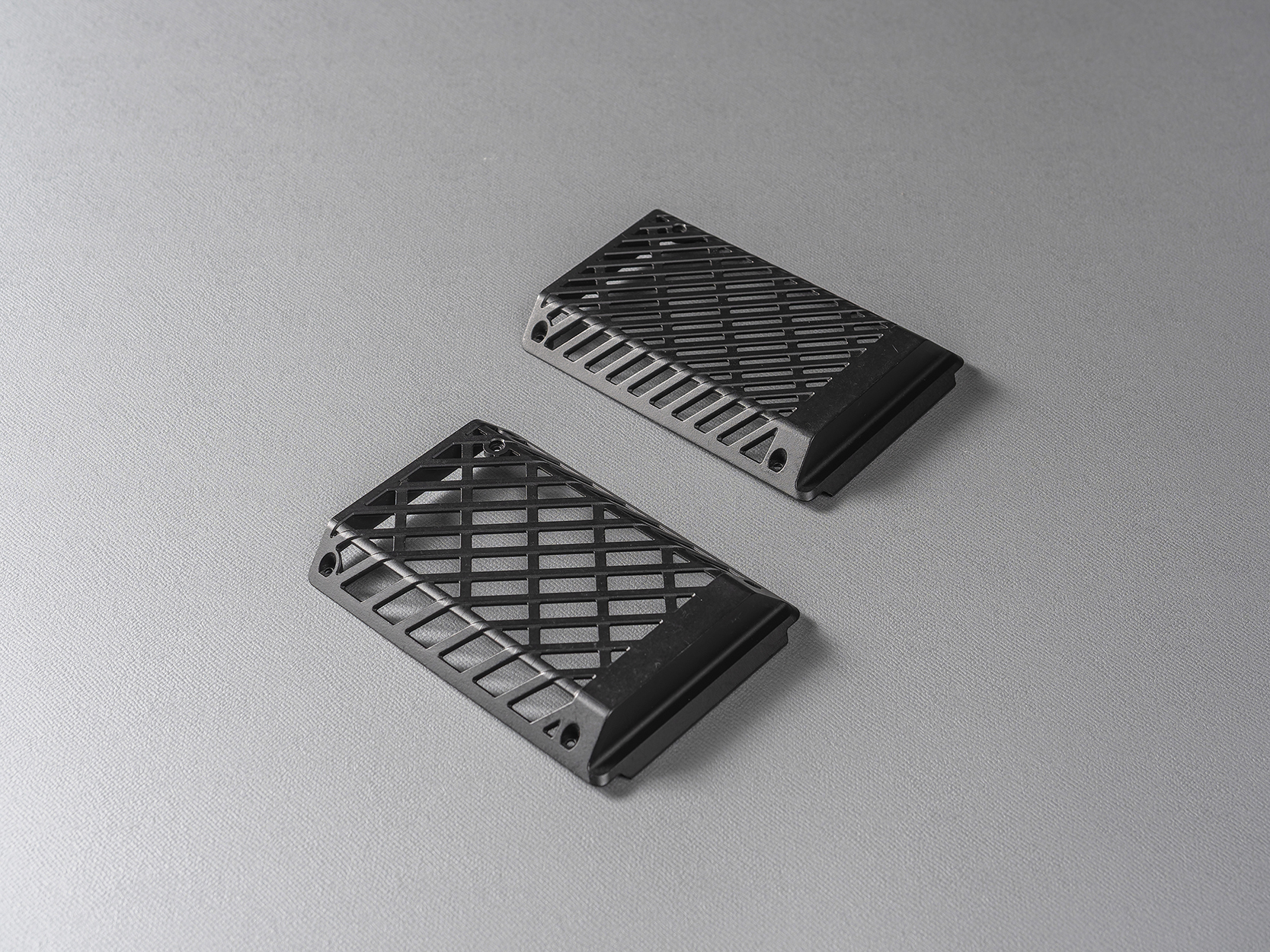

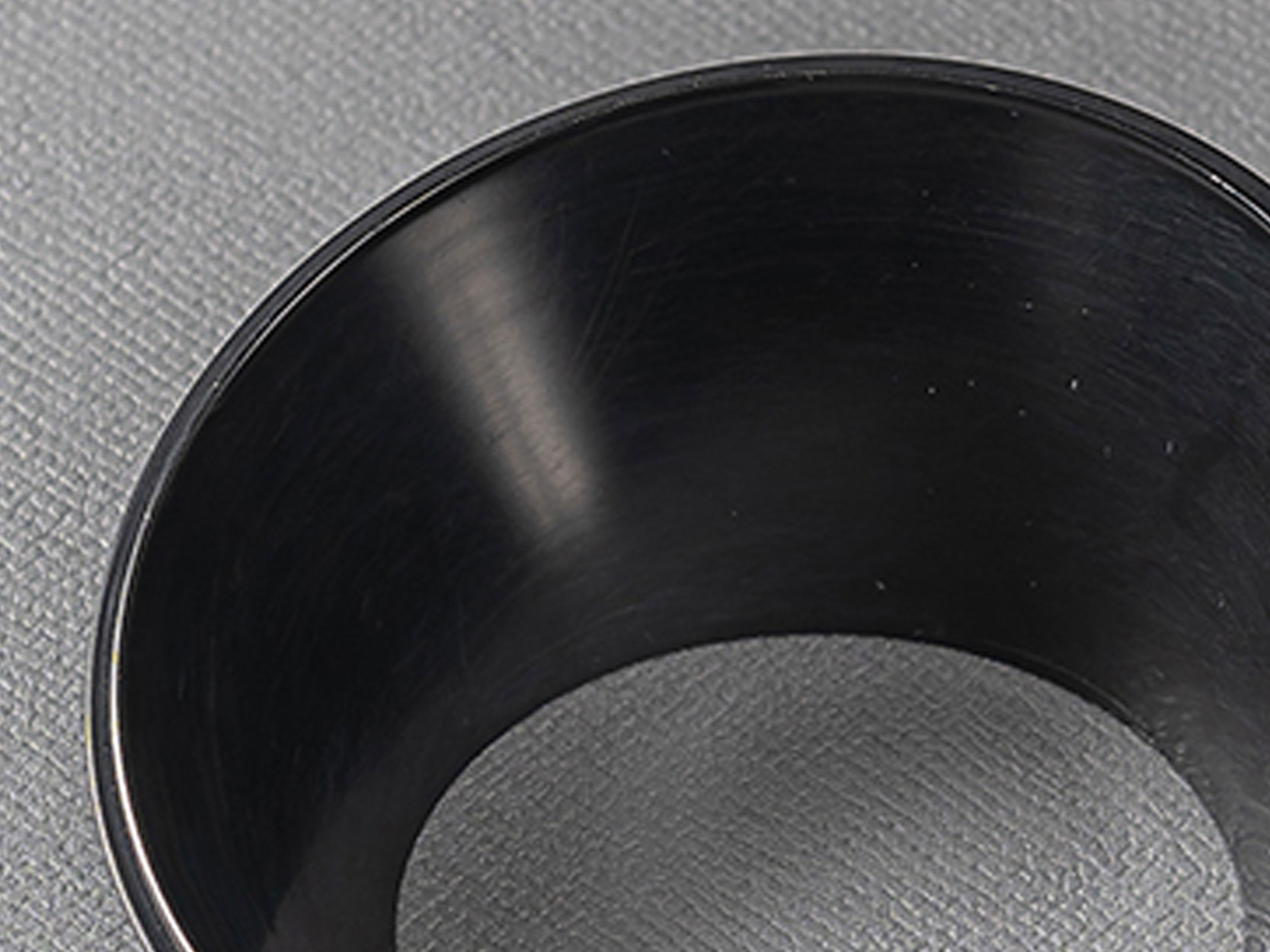

Anodized Black Aluminum

Aluminum that has undergone black anodizing treatment offers the high corrosion and wear resistance, along with a beautiful finish. The black surface reduces light reflection, and provides a subtle, unobtrusive appearance. Additionally, the anodized layer is hard, which increases mechanical strength, making it suitable for the industrial applications. Furthermore, because it’s an environmentally friendly treatment process, it is also appreciated as an environmentally conscious product.

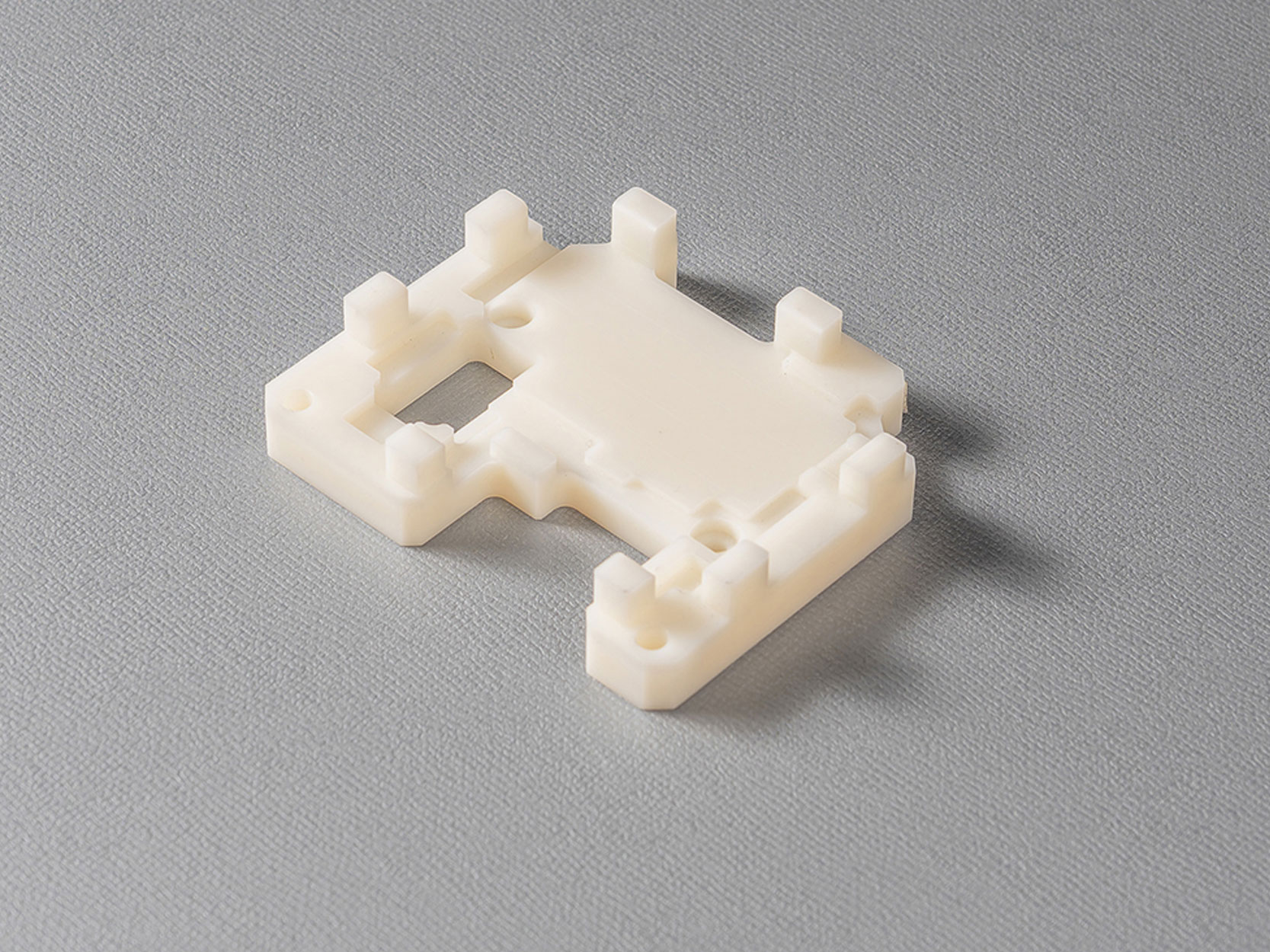

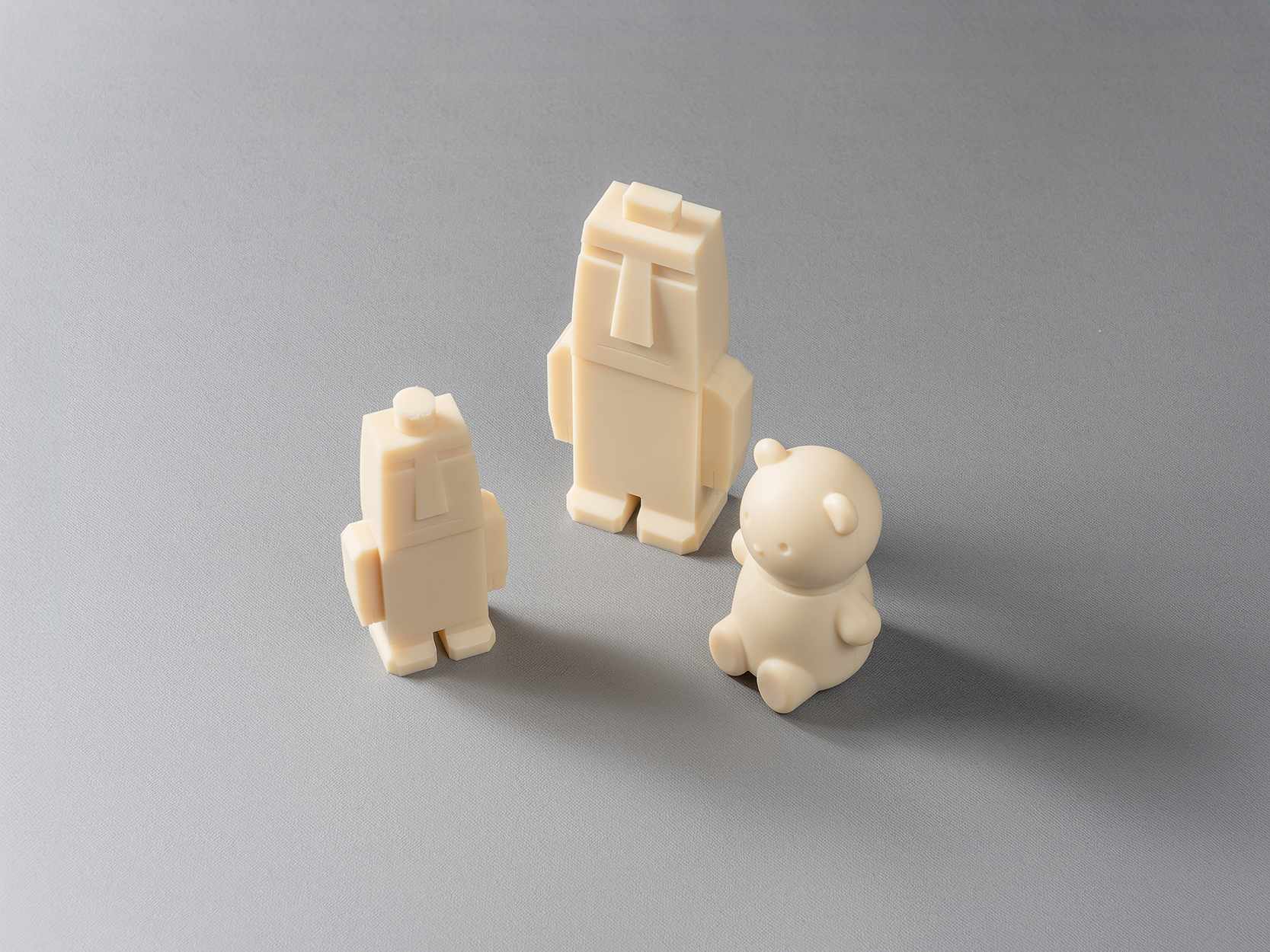

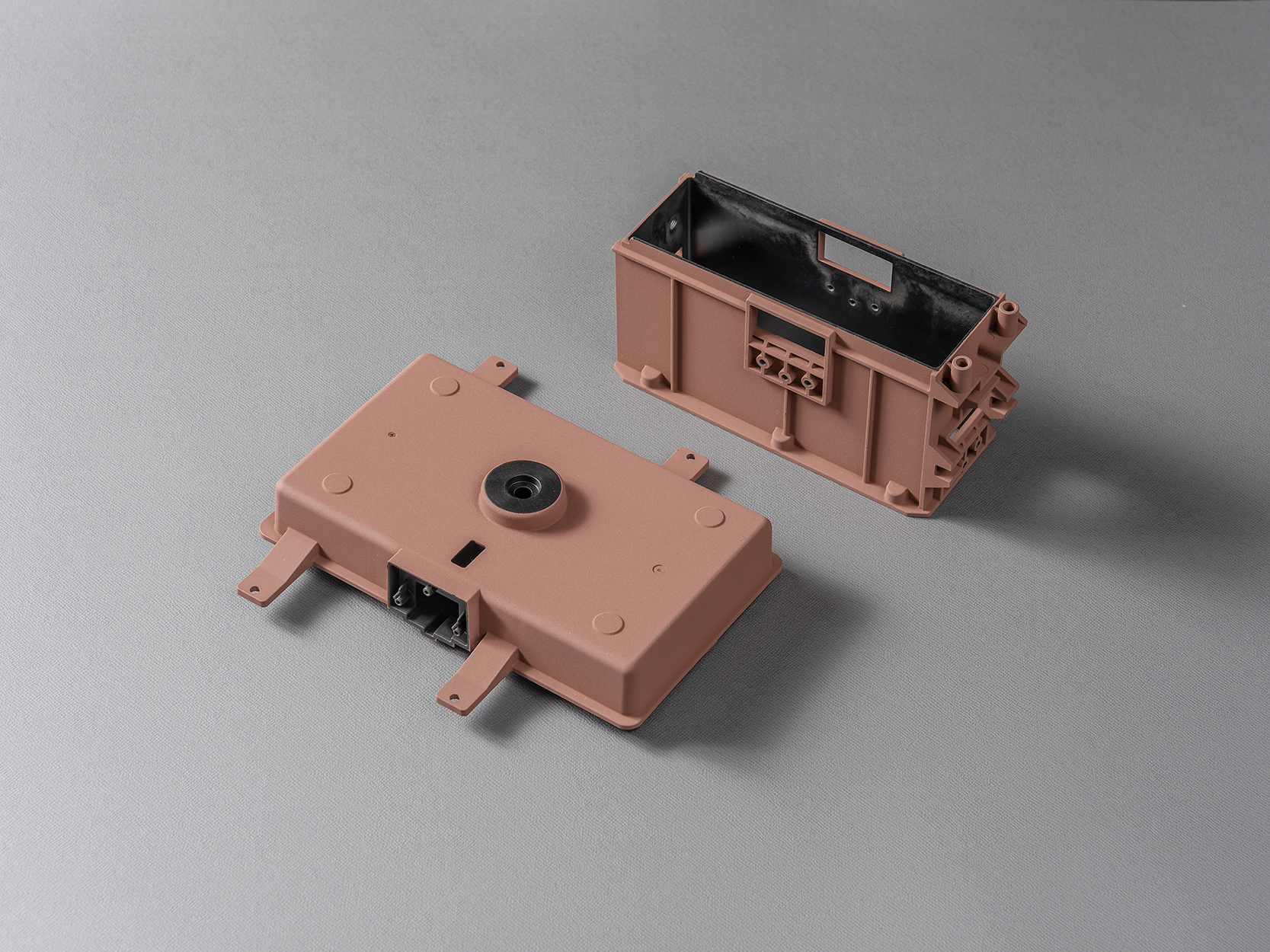

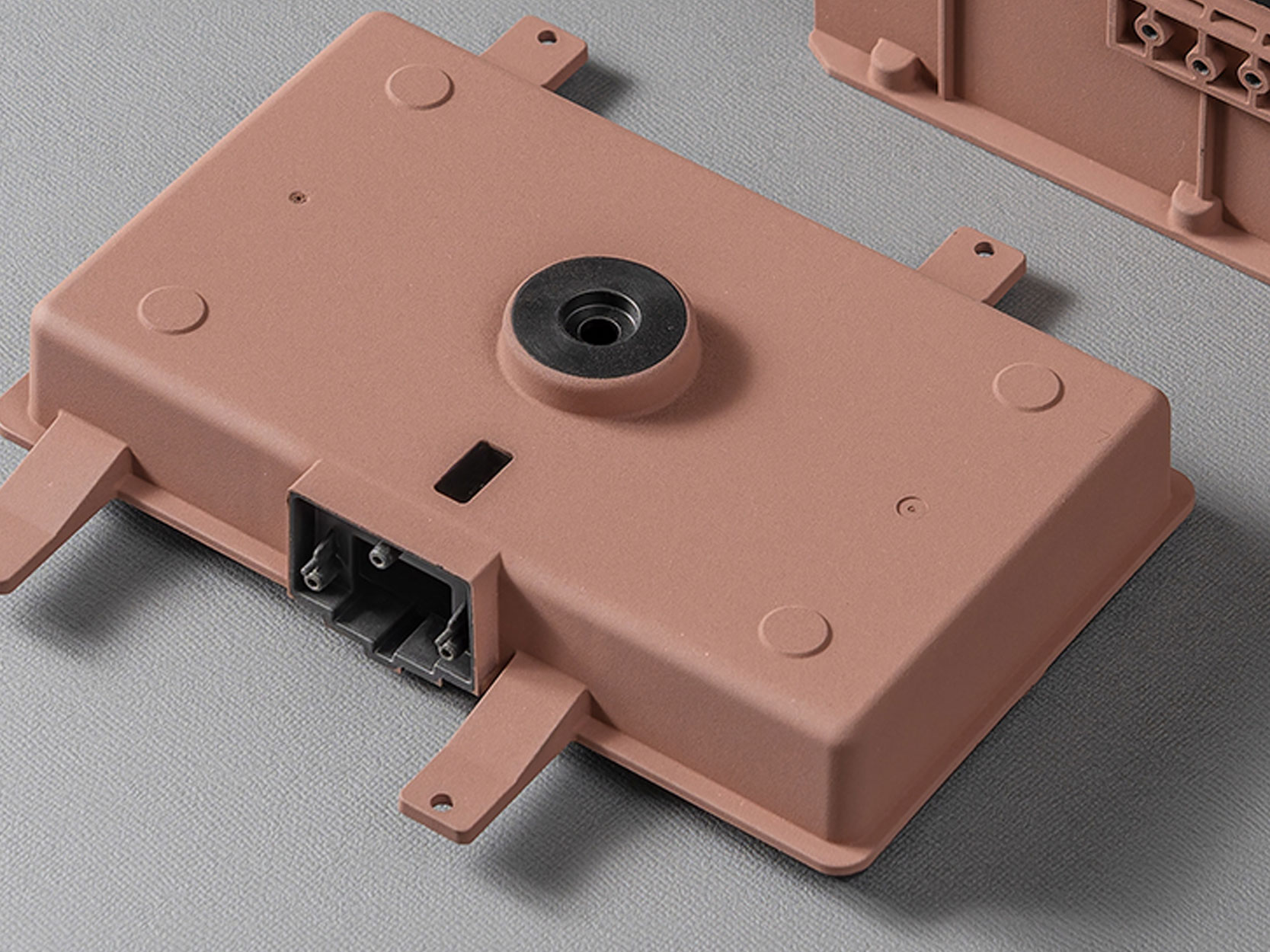

Cast Products (Rigid Urethane)

Cast products (rigid urethane) are products made from rigid urethane resin, known for their lightweight yet high-strength properties. By pouring the resin into a mold and allowing it to cure, precise shapes can be achieved, making them suitable for a wide range of applications. These products offer excellent heat resistance and chemical resistance, and are widely used in construction materials, automotive parts, industrial equipment, and more. They are also easy to process, and custom-made products can be manufactured as well.

Silicone Resin Molding Products

Silicone resin molding uses resin molds to create silicone products with complex shapes. Liquid silicone is poured into the resin mold, where it is cured to form the finished product.

Silicone rubber is known for its excellent heat resistance, cold resistance, and electrical insulation properties, making it suitable for a wide range of applications.